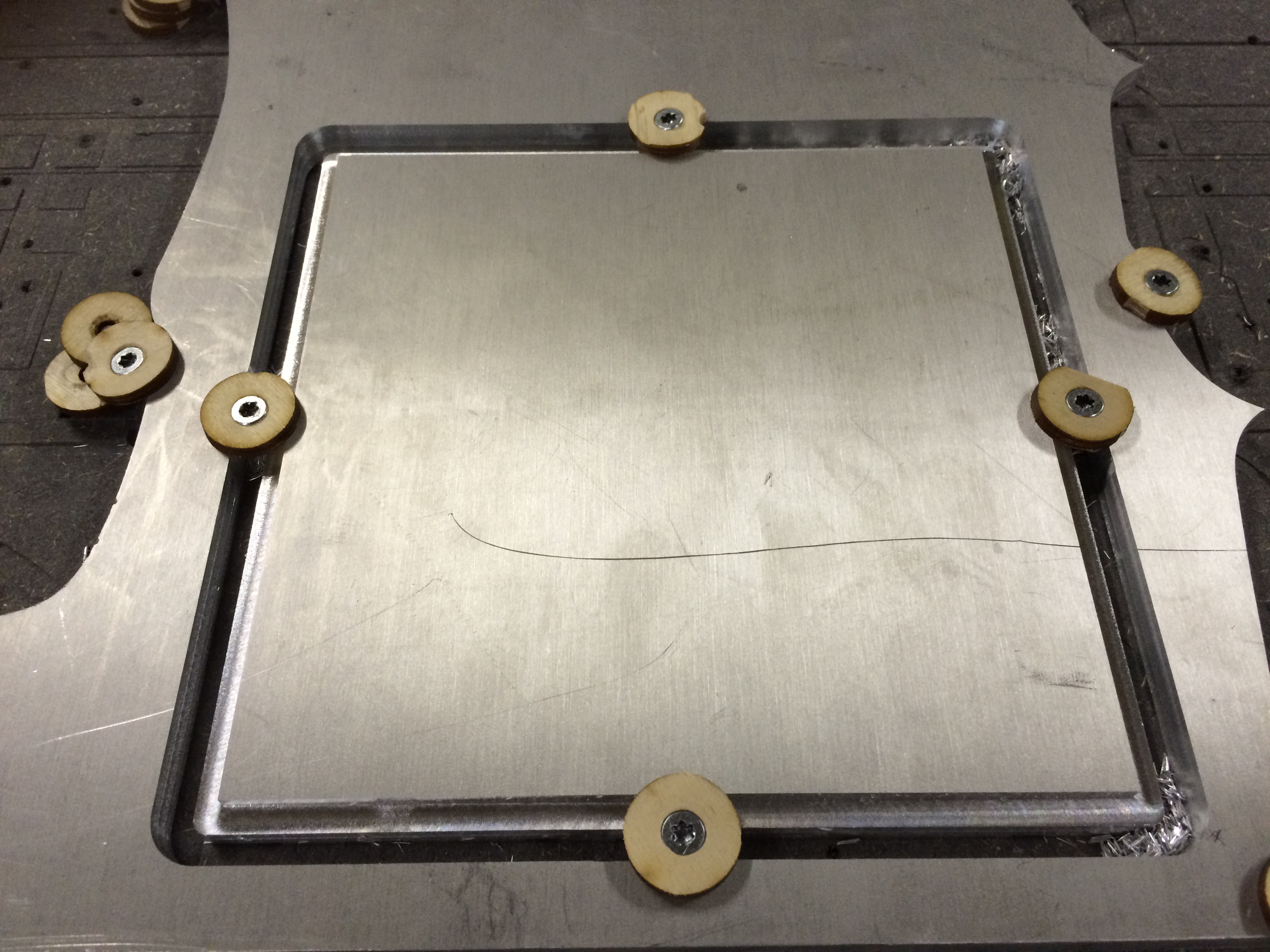

A pressing rig for making sheet material from waste. First tests are with PLA (bio plastic) and wood waste from CNC milling. Designed to be fabricatable on a large format CNC mill. We use a ShopBot PRS alpha to fabricate the parts.

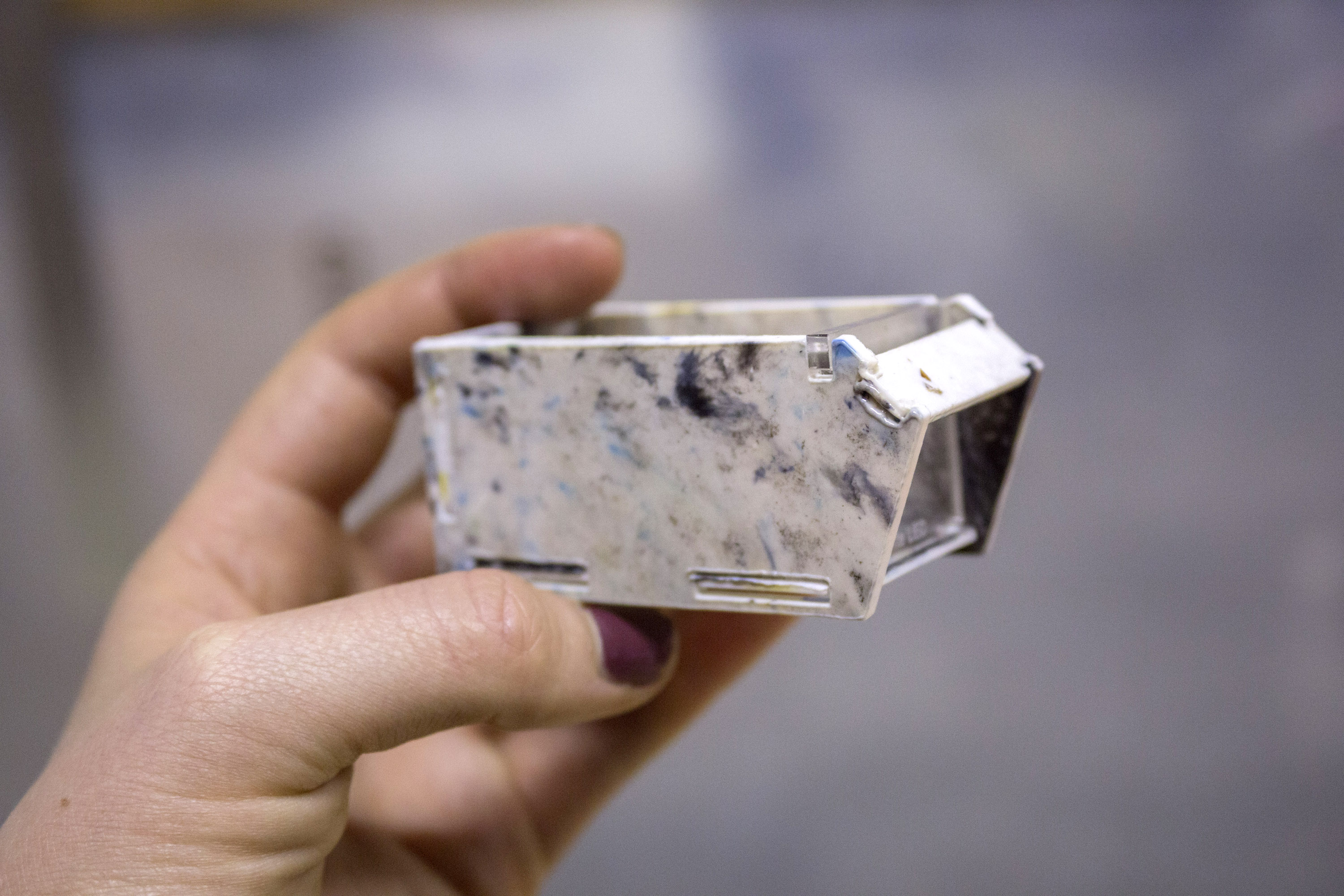

Currently testing first mold box. Heating is done by placing mold on a cooking plate. Watercooling by submerging boxmold and hydraulic press in a bucket of water. Results are promising. A twosided heat source is needed for even sheets.

- Test top side heating with 220v cartridge heater

- Develop water cooling system by engraving aluimium plates.

- Develop heat and pressure monitoring

- Test vacuum clamping/bagging to replace hydraulic pressing. Much cheaper to scale if it works.

- Make mold for lasercutter sized sheets

- Make a full size (2.5m x 1.25m) mold

- Develop a system for automating the sheet pressing

- Make locally recycled plates a viable option for users of fab labs and makerspaces

- Envrionment - Reduce negative impact on our panet from consuming resources

- Economic - Make making good stuff more affordable

- Inspiration - Put awareness and supply chain consciousness on the agenda

- Skills - Make tools that build deeper inights into material properties