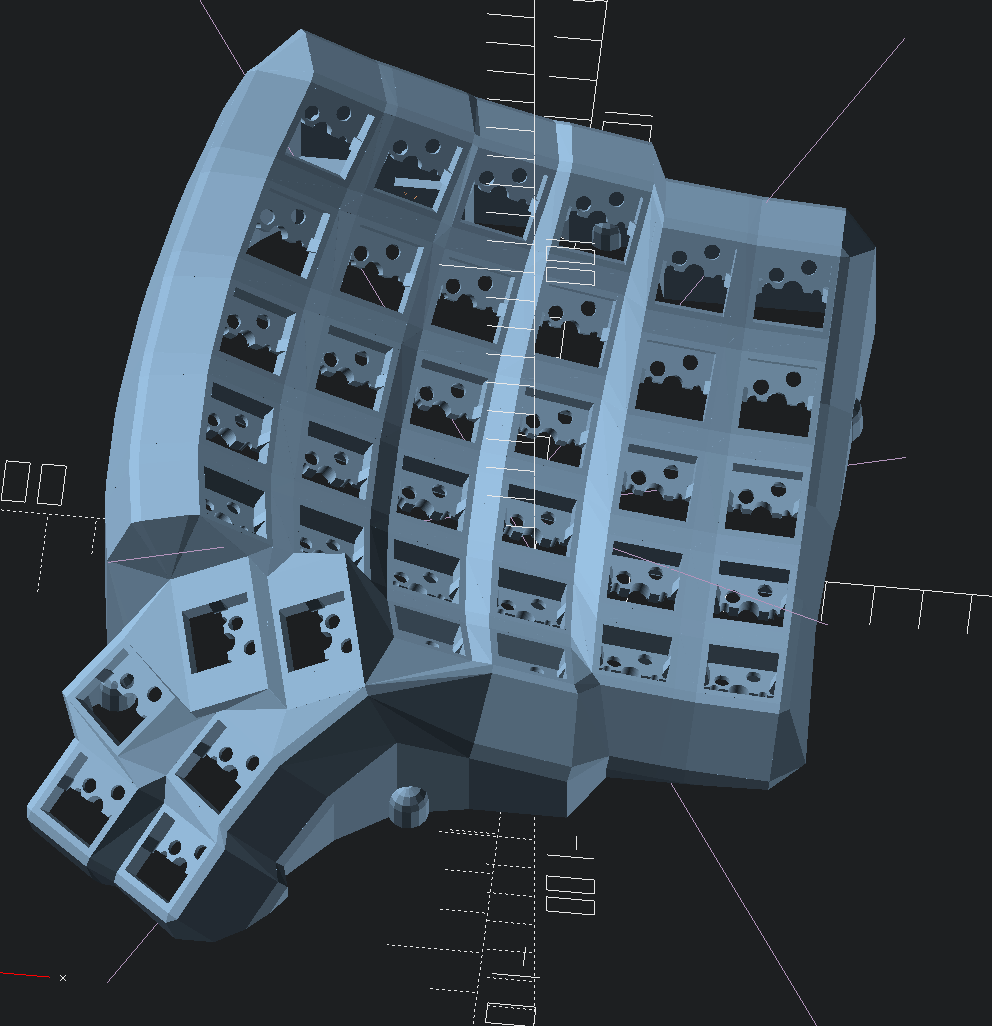

This is a fork of Dactyl-Manuform by Tom Short, which itself is a fork of Dactyl by Matthew Adereth, a parameterized, split-hand, concave, columnar, ergonomic keyboard.

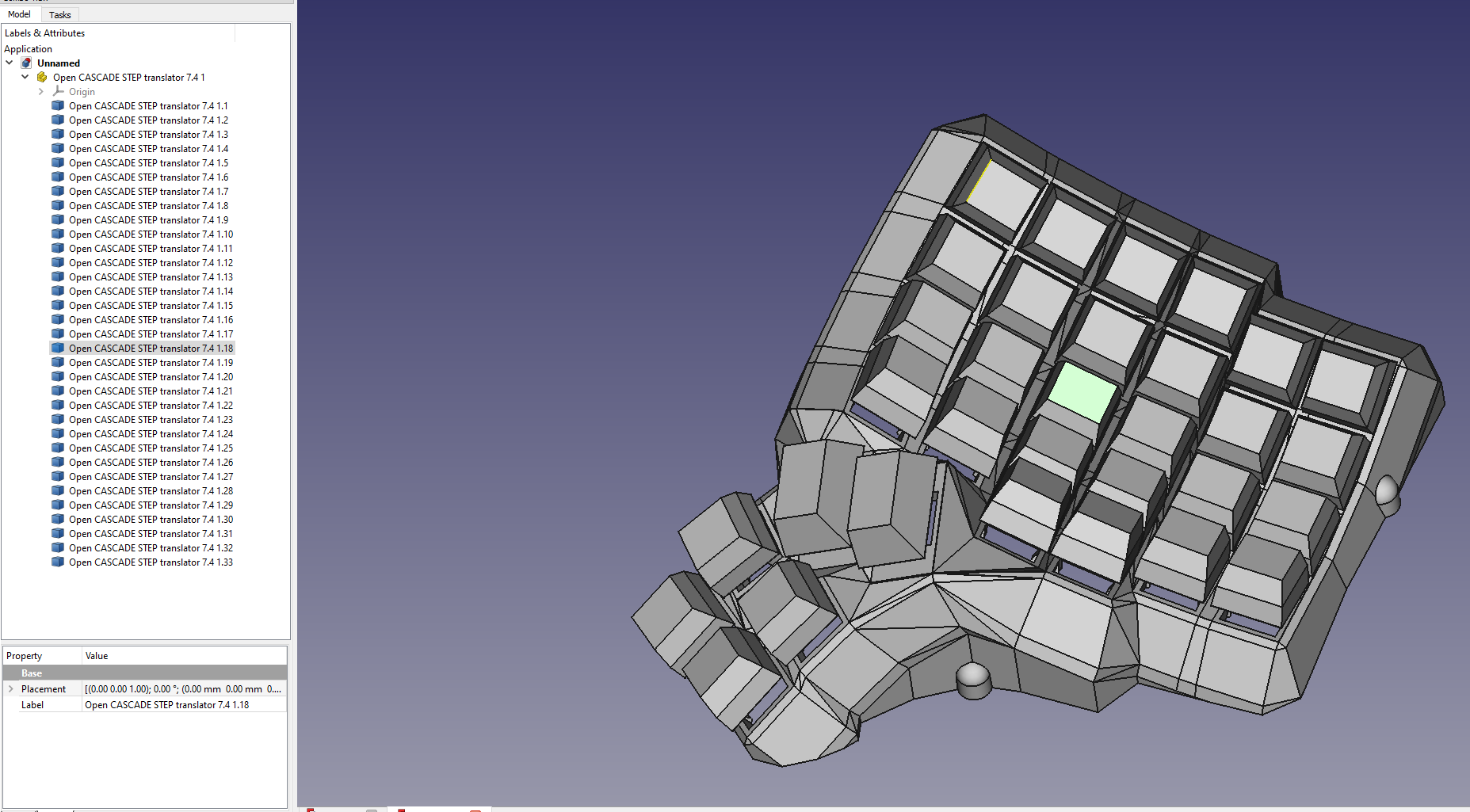

While the code structure remains comparable to the original, Clojure and OpenSCAD have been replaced by Python and cadquery/OpenCASCADE. The predecessors were exceptional contributions to the ergo keyboard community by the authors but used a rather esoteric programming language, Clojure, and a relatively inconsistent geometry engine, OpenSCAD. My hope is that by converting the code the community will have an easier time modifying and evolving this design.

As part of the effort to create a new engine I converted the code to cadquery/OpenCASCADE. While OpenSCAD has provided an open source 3D engine that is extremely popular, it frankly creates barely passable STLs when you have complex geometry. After being extremely frustrated trying to fix the mesh I realized it is just not a stable engine to create high quality files. OpenCASCADE is extremely powerful but requires extensive detail to operate. cadquery provided an excellent platform to run a stable geometry engine with a simplified API.

Tired of hot glue and constraining the socket with "nubs"? I've added an adjustable undercut for using the clips on the sockets. May require some tweaking and little filing, but I have my DM built without any glue and you can too. Just use plate_style = 'UNDERCUT'.

Added a new switch for hot swap and a way to include any additional geometry in the key plate by use of an imported file. For hot swap just use plate_style = 'HS_HOLE' or plate_style = 'HS_NUB'. To import an arbitrary geometry set the plate_file = None and plate_offset = 0.0. The file must be .step for OpenCascade / cadquery and .stl for openSCAD / solid python. The zero reference should be the key center (XY), and the top of the plate (Z). Plate offset is a Z-axis translation for minor adjustments without modifying the geometry file.

DISCLAIMER: I have not built the hot swap version and cannot speak to the geometry. I found it running around in various places and don't know the origin. At least one user has claimed it works.

If you know the origin I would like to credit the originator. If you test it I'd love to know how well it works or if you come up with a better geometry I'm happy to add it.

Message me on Reddit u/j_oshreve if you are really stuck. I don't have much time to help, but can answer the occasional question. Also feel free to put in a pull request if you come up with something crafty and want to give others access to it.

Added an external mount for a separate controller tray. Looks to work with lolligag's controller trays / holders:

Just use controller_mount_type = 'EXTERNAL'.

This is a new feature so any feedback is appreciated. If you have issues, message me on Reddit and I will try to help correct them.

Added 3 OLED mounts. Have printed them stand alone with success.

oled_mount_type = 'CLIP' creates an opening to set the OLED with a clip on face plate to hold it down. This is the preferred mounting, but needs the OLED to have a removable connection.

oled_mount_type = 'SLIDING' creates an opening such that you can slide the screen up through the back and into place. Needs a piece of foam or a bit of glue to lock in place.

oled_mount_type = 'UNDERCUT' creates an opening with an undercut to create whatever custom holder you want. Will not work without additional part creation from the user.

This is a new feature so any feedback is appreciated. If you have issues, message me on Reddit and I will try to help correct them.

FWIW, the cadquery version is essentially a double translation and is now a bit of a mess. I wanted to share with the community as the first version of dactyl-manuform that exports as a STEP file, allowing easier editing. I have decided to use this code to try new geometries and features to share. I am still working on a new generator, but feel this one can continue to evolve and inform the other effort.

The majority of the the rest of the below content is as defined by previous authors, except where noted.

The main change is that the thumb cluster was adapted from the ManuForm keyboard (geekhack). The walls were changed to just drop to the floor. The keyboard is paramaterized to allow adjusting the following:

- Rows: 4 - 6

- Columns: 5 and up

- Row curvature

- Column curvature

- Row tilt (tenting)

- Column tilt

- Column offsets

- Height

Setting up the Python environment - NEW

- Install Python 3.X or use your favorite distro / platform (Anaconda)

- It is advisable, but not necessary, to setup a virtual environment to prevent package/library incompatibility

- Install Numpy, easiest method is

pip install numpyorpip3 install numpyon linux.

cadquery install

- Install scipy, easiest method is

pip install scipyorpip3 install scipyon linux. - Install cadquery, many options (see link), but easiest method is

conda install -c conda-forge -c cadquery cadquery=2. Props to the creators/maintainers, this has the power of Open CASCADE with nearing the simplicity of OpenSCAD.

OpenSCAD install

- Install SolidPython, easiest method is

pip install solidpythonorpip3 install solidpythonon linux. - Install OpenSCAD

Generating the cadquery design - NEW

- Run

python dactyl_manuform_cadquery.pyorpython3 dactyl_manuform_cadquery.py - This will regenerate the

things/*.stepfilesleft_py.stepright_py.stepplate_py.step

- Use FreeCAD or other program to open a

.stepfile. - Export functions can be modified to export stl directly if desired. When done, use FreeCAD or other CAD program to modify, edit, or export to STL.

Generating the OpenSCAD design - NEW

- Run

python dactyl_manuform.pyorpython3 dactyl_manuform.py - This will regenerate the

things/*.scadfilesleft_py.scadright_py.scadplate_py.scad

- Use OpenSCAD to open a

.scadfile. - Make changes to design, repeat run step, OpenSCAD will watch for changes and re-render.

- When done, use OpenSCAD to export STL files

Pre-generated STL files are available in the things/ directory. When a model is generated, it also generates a model for a bottom plate. This can be exported to a DXF file in OpenSCAD. The things/ directory also has DXF files for the bottom plate. When laser cut, some of the inside cuts will need to be removed.

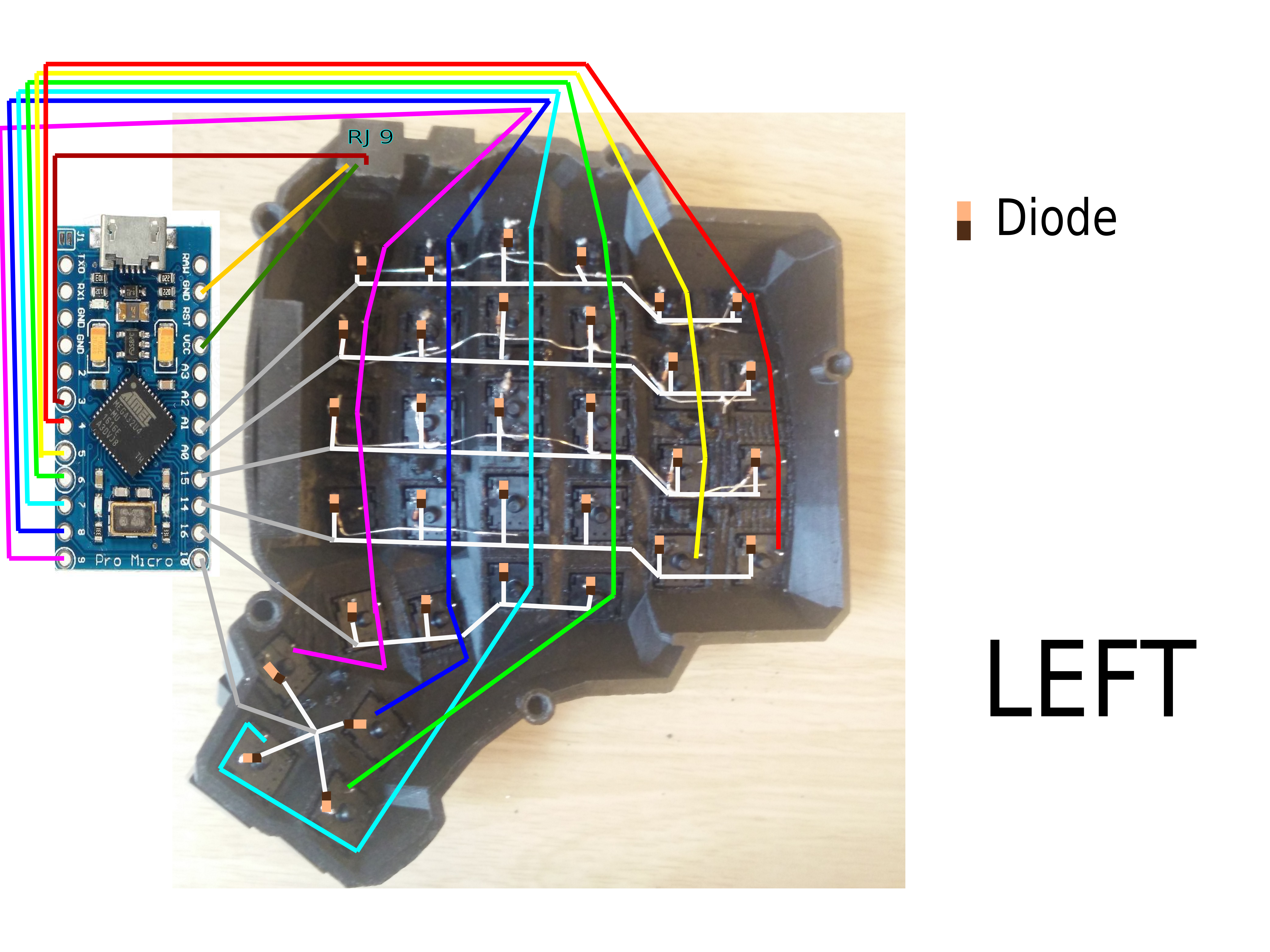

Here are materials tshort used for wiring.

- Two Arduino Pro Micros

- Heat-set inserts

- M3 wafer-head screws, 5mm

- Copper tape

- #32 magnet wire

- #30 wire

- 3-mm cast acrylic

- Veroboard stripboard

- 1N4148 diodes

- Female RJ-9 connectors

I wired one half using the traditional approach of using the legs of a diode to form the row connections. (I'm not great at soldering, so this was challenging for me.) For this side, I used magnet wire to wire columns. That worked okay. The magnet wire is small enough, it wants to move around, and it's hard to tell if you have a good connection.

For another half, I used stripboard for the row connections. This allowed me to presolder all of the diodes. Then, I hot-glued this in place and finished the soldering of the other diode ends. I like this approach quite a lot. Connections for the diodes were much easier with one end fixed down. On this half, I also used copper tape to connect columns. This worked a bit better than the magnet wire for me. For a future version, I may try just bare tinned copper wire for columns (something like #20). With the stripboard, it's pretty easy keeping row and column connections separate.

Note that a telephone handset cable has leads that are reversed, so take this into account when connecting these leads to the controller.

The 3D printed part is the main keyboard. You can attach a bottom plate with screws. The case has holes for heat-set inserts designed to hold 3- to 6-mm long M3 screws. Then, I used wafer-head screws to connect a bottom plate. If wires aren't dangling, a bottom plate may not be needed. You need something on the bottom to keep the keyboard from sliding around. Without a plate, you could use a rubber pad, or you could dip the bottom of the keyboard in PlastiDip.

For more photos of the first complete wiring of v0.4, see Imgur.

This is how the rows/columns wire to the keys and the ProMicro

NOTE: you also make sure the firmware is set up correctly (ex: change row pins with col pins)

Firmware goes hand in hand with how you wire the circuit. I adapted the QMK firmware here. This allows each side to work separately or together. This site also shows connections for the Arduino Pro Micro controllers.

Copyright © 2015-2020 Matthew Adereth, Tom Short, and Joshua Shreve

The source code for generating the models (everything excluding the things/ and resources/ directories is distributed under the GNU AFFERO GENERAL PUBLIC LICENSE Version 3. The generated models and PCB designs are distributed under the Creative Commons Attribution-NonCommercial-ShareAlike License Version 3.0.