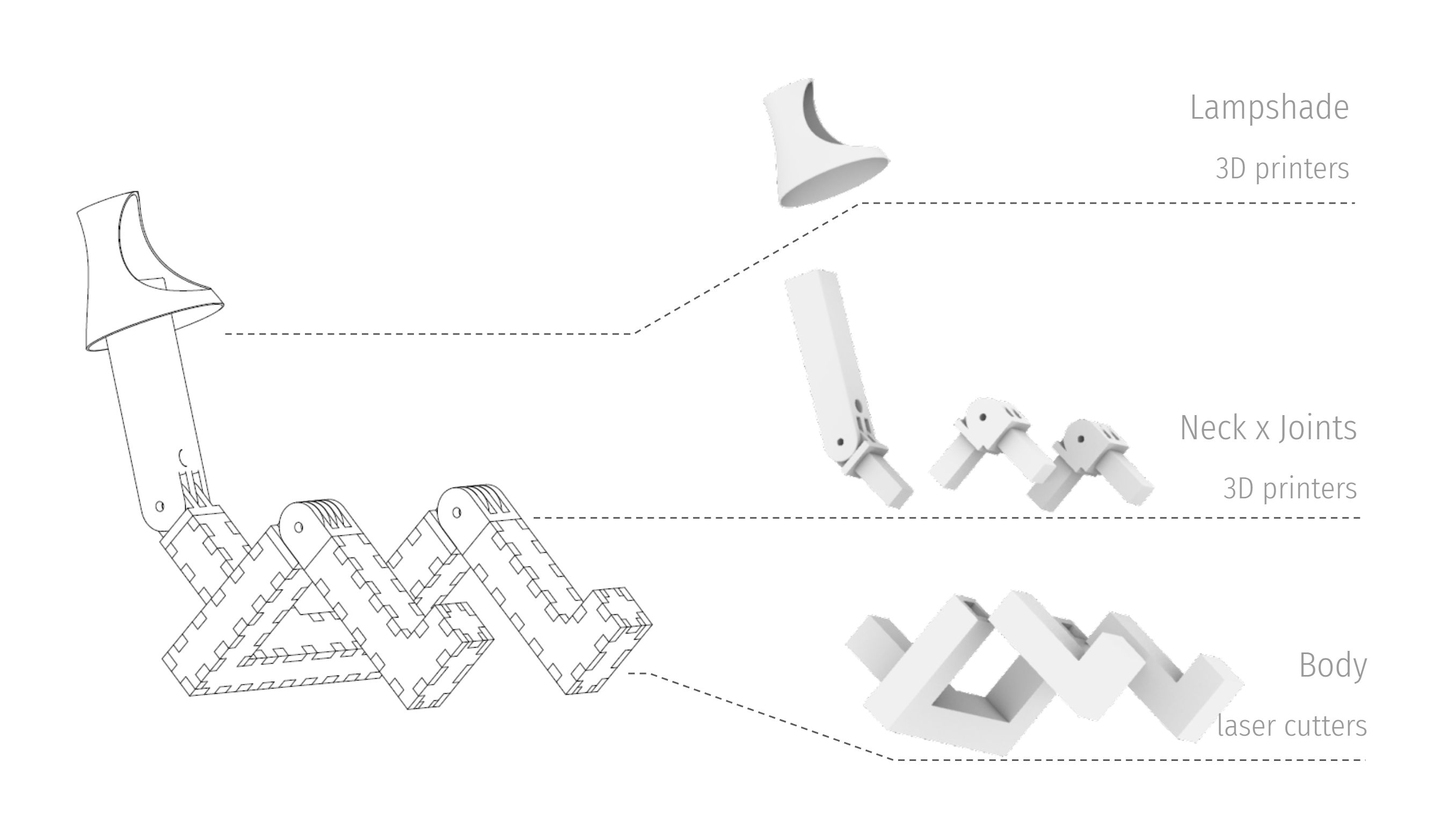

Computer Aided Manufacturing Project : utilizing 3D printers and laser cutters.

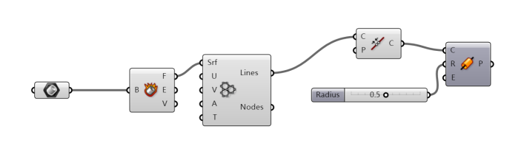

- Hexagonal Structure on the surface.

- Join the curve of Hexagonal Lines.

- Create a pipe surface around a rail curve with 0.5 cm radius.

- Hexagonal Structure to decorate lampshade surface in Grasshopper.

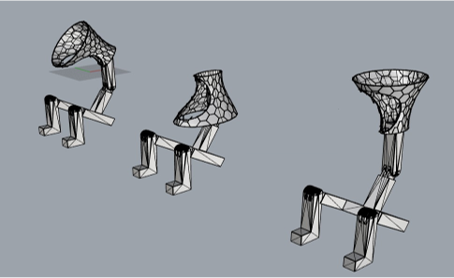

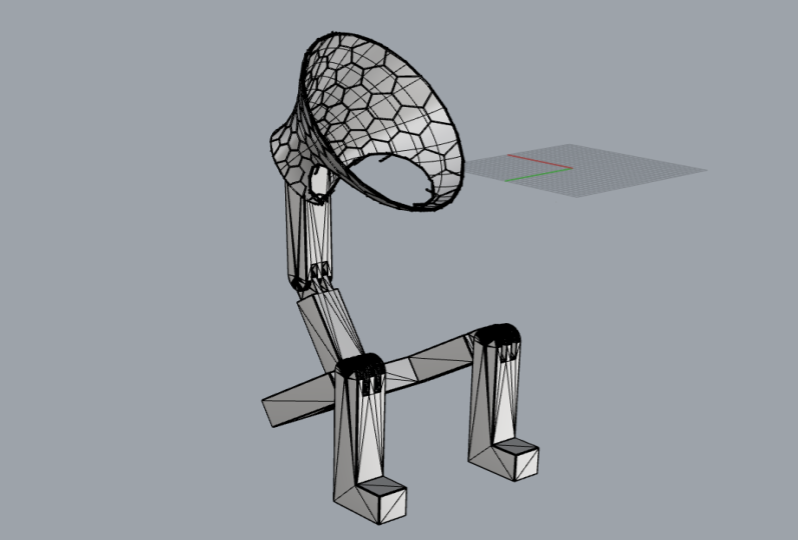

- Concepts & shapes of lamp model.

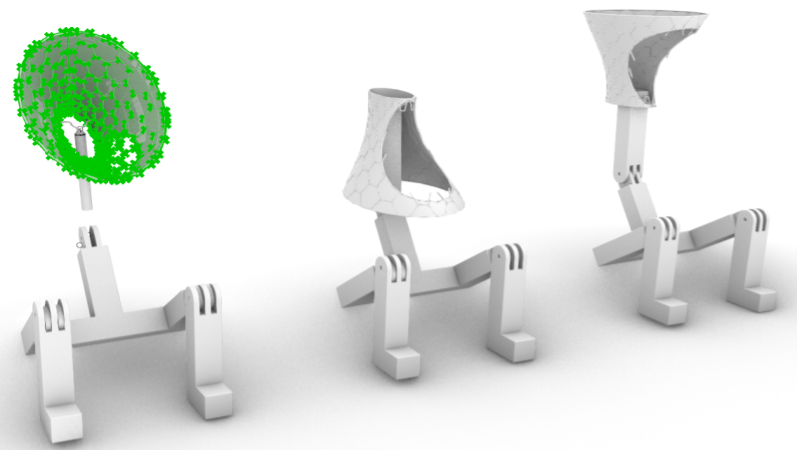

- Rendered display mode of these lamp model.

- Final program of lamp modeling in Rhino 7.

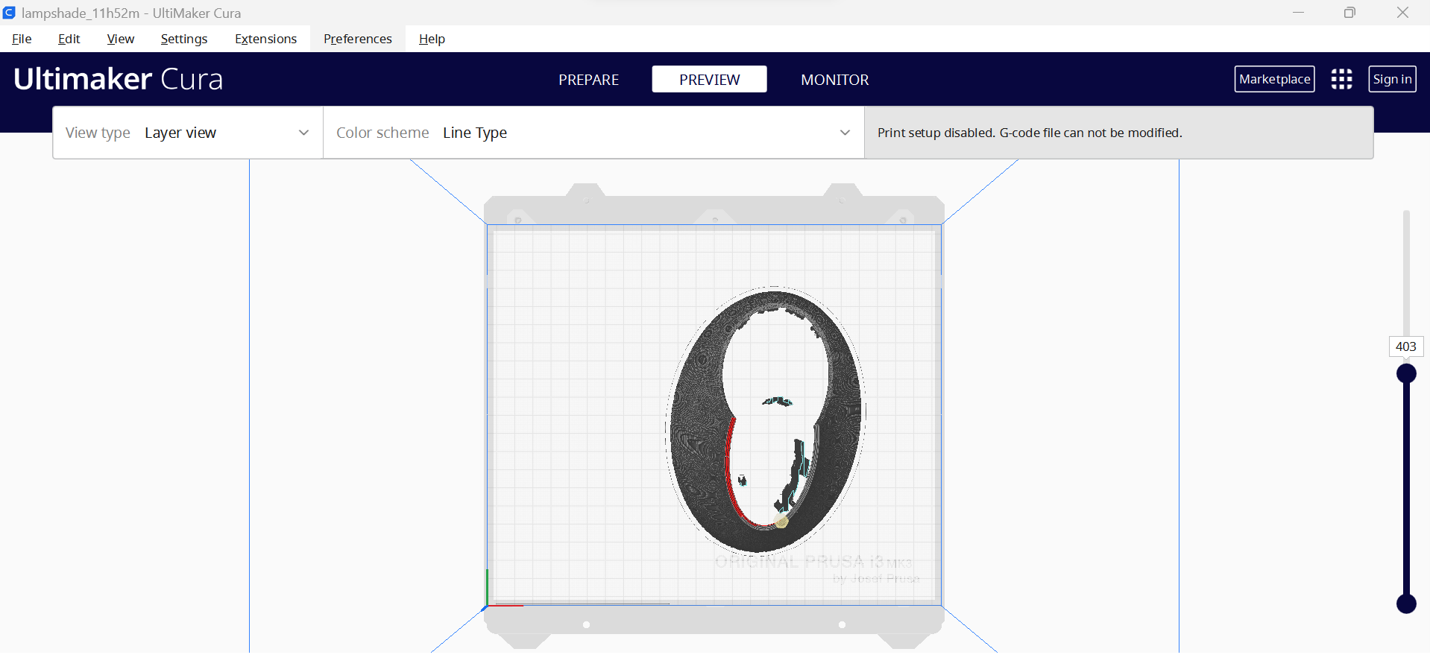

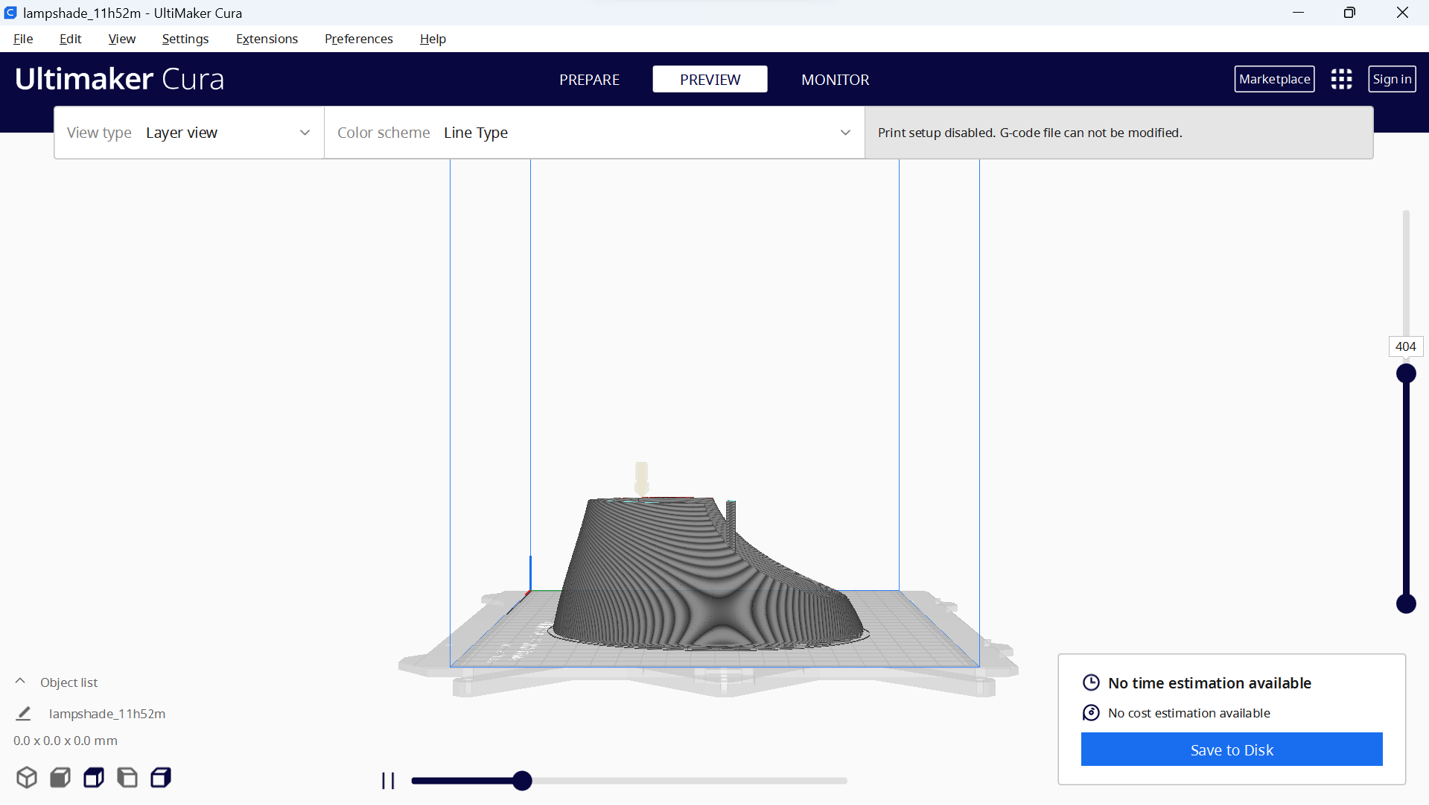

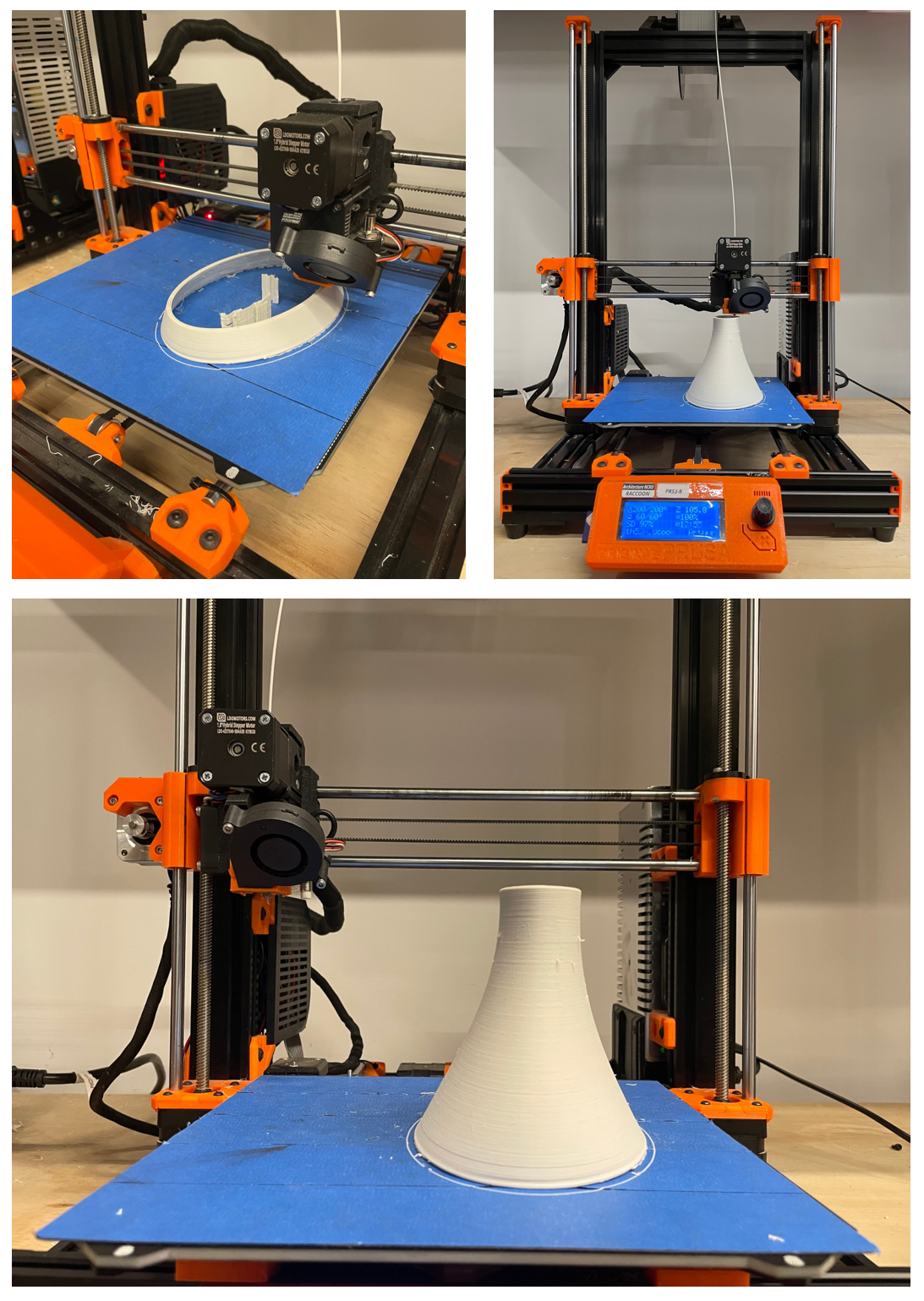

- Layer Height: 0.2 mm

- Wall Thickness: 0.8 mm

- Infill Density: 5.0 %

- Infill Pattern: Grid

- Printing Temperature:200.0°C

- Print Speed:60.0 mm/s

- Initial Layer Speed:30.0mm/s

- Build Plate Adhesion Type:Skirt

- Top view of lamp shade model for the simulation slicing for 3D printers in Ultimaker Cura.

- Right view of lamp shade model for the simulation slicing for 3D printers in Ultimaker Cura.

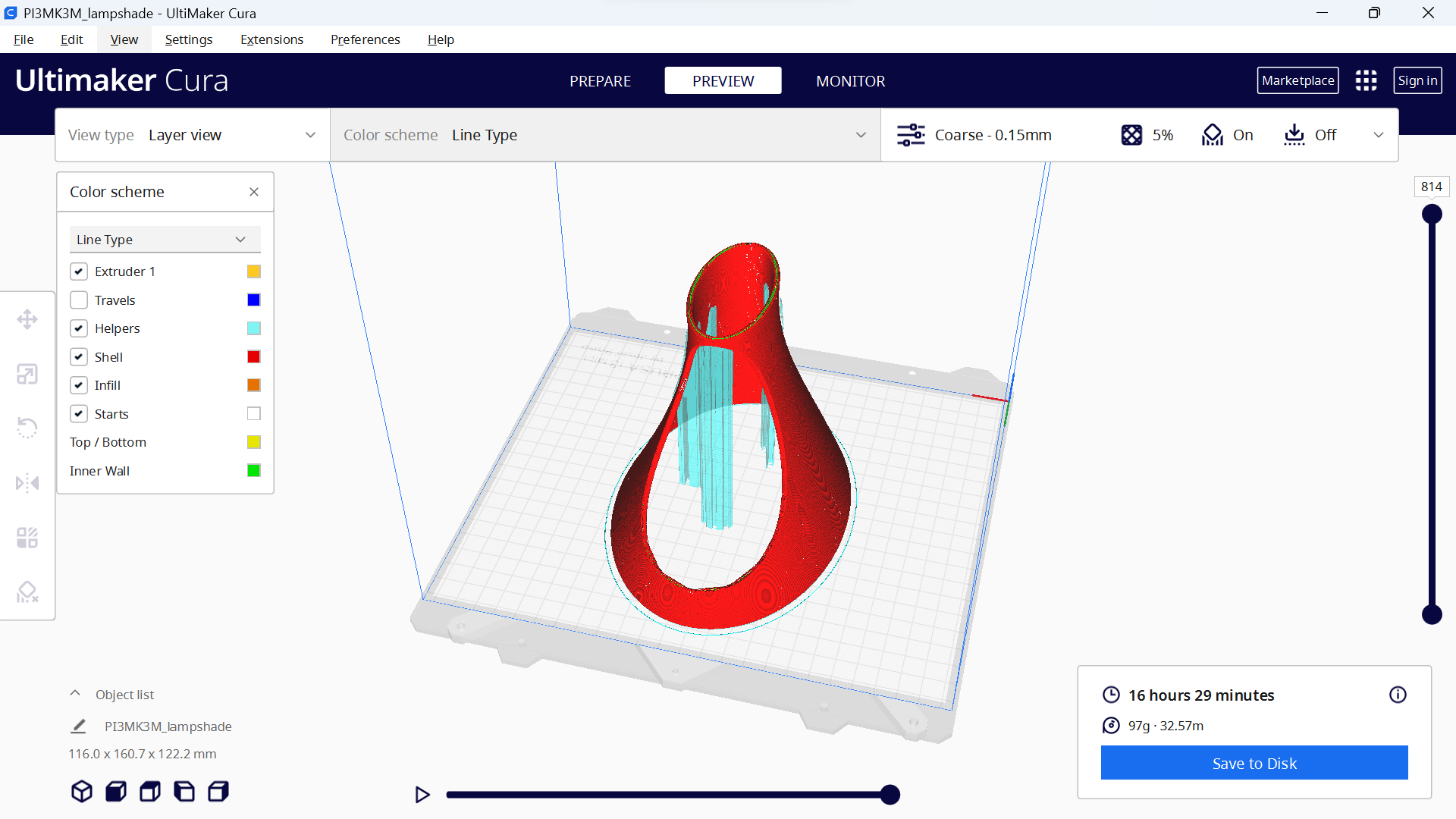

- The slicing lamp shade model in line type of color scheme for 3D printers in Ultimaker Cura.

- Too thin of a wall is easy to collapse the bottom and support structure.

- The printing path in the Z-axis value is over setting.

- The initial speed is too fast to make sure a completed printing process.

- printing process and result of lamp shade model in PLA.

- Utilize “offsetsrf” command to thicken the surface into

- Reduce the speed by tuning the 3D printer setting after the 9 times calibration of horizontal foundation.

- The initial speed is too fast to make sure a completed printing process.

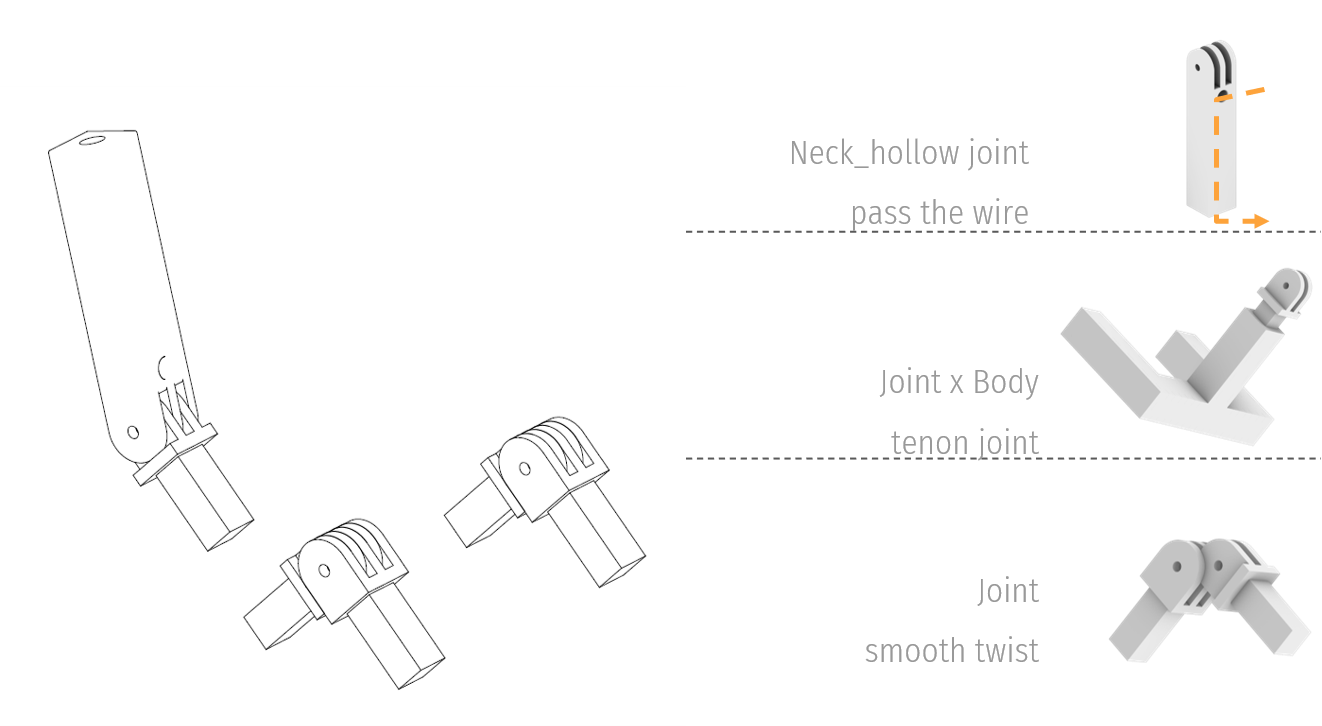

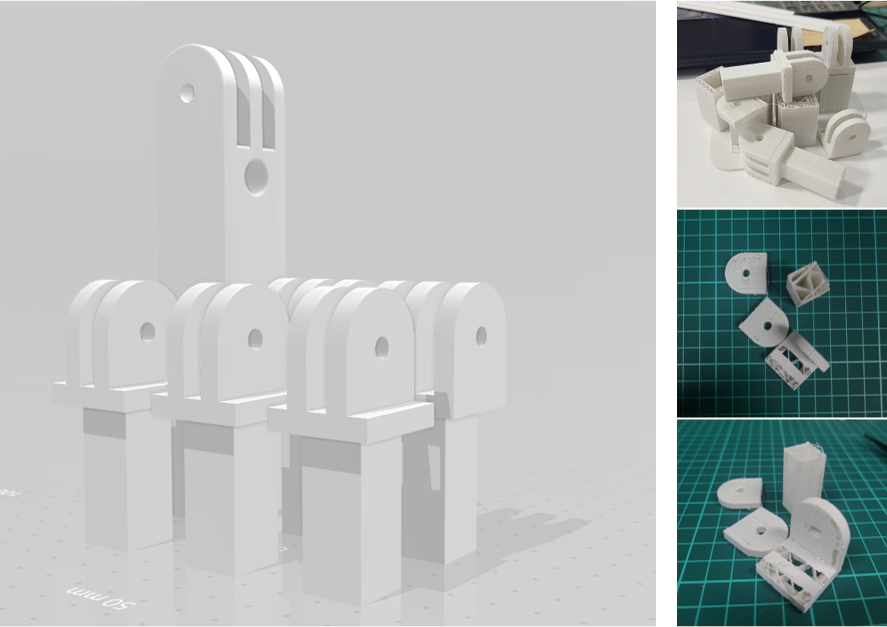

- Made by 3D printers with PLA.

- Layer Height: 0.3 mm

- Wall Thickness: 0.3 mm

- Infill Density: 10 %

- Infill Pattern: Triangles

- Easy to break between layers

- Wall should increase density

- Infill is not enough to be a joint (20~30%)

- Layer Height: 0.2 mm

- Wall Thickness: 0.8 mm

- Infill Density: 20 %

- Infill Pattern: Triangles

- Overly strong support

- Wall (top) quality is still poor

- Support is not as expected

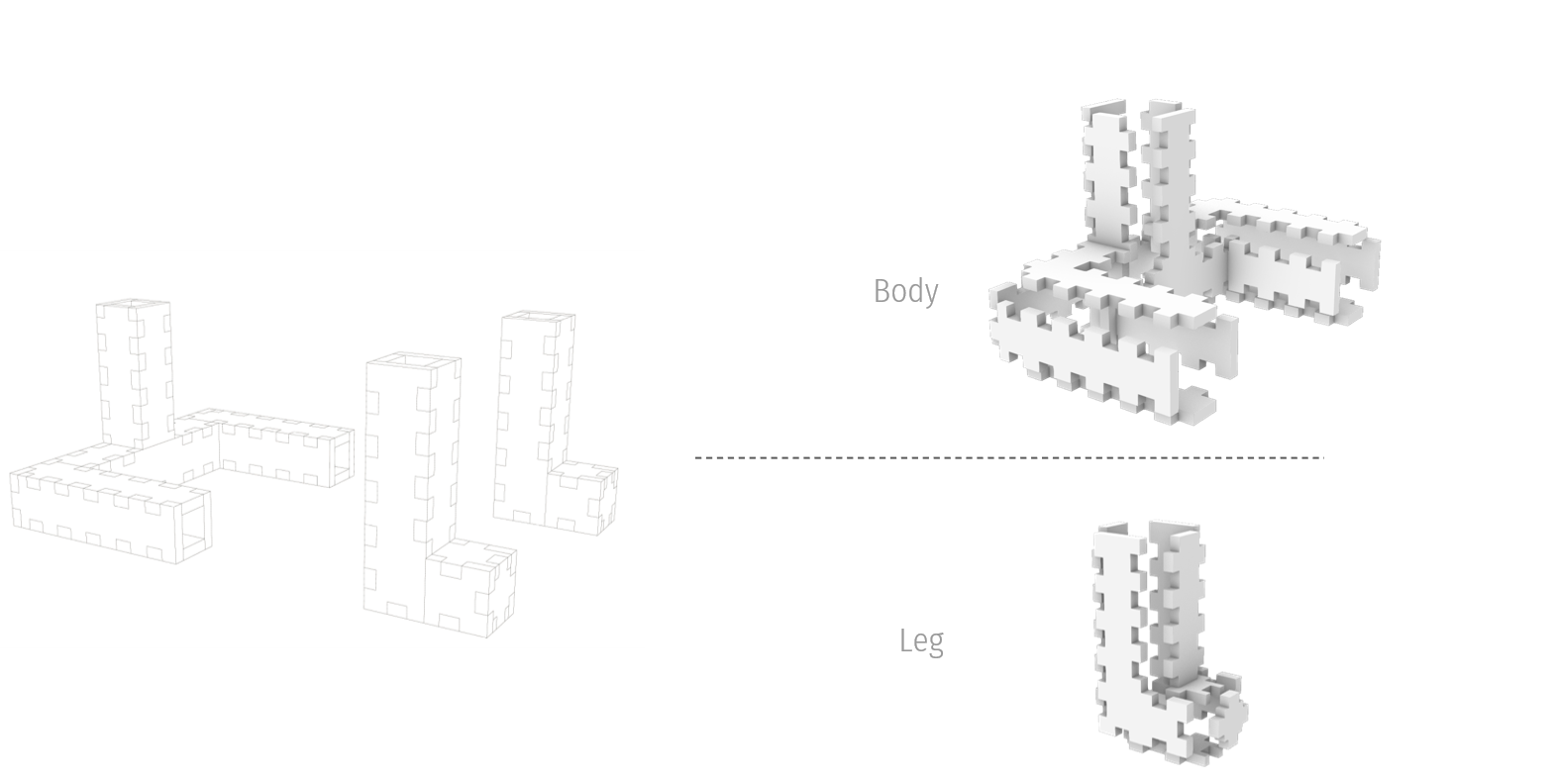

- Topological interlocking in assembly procedure.

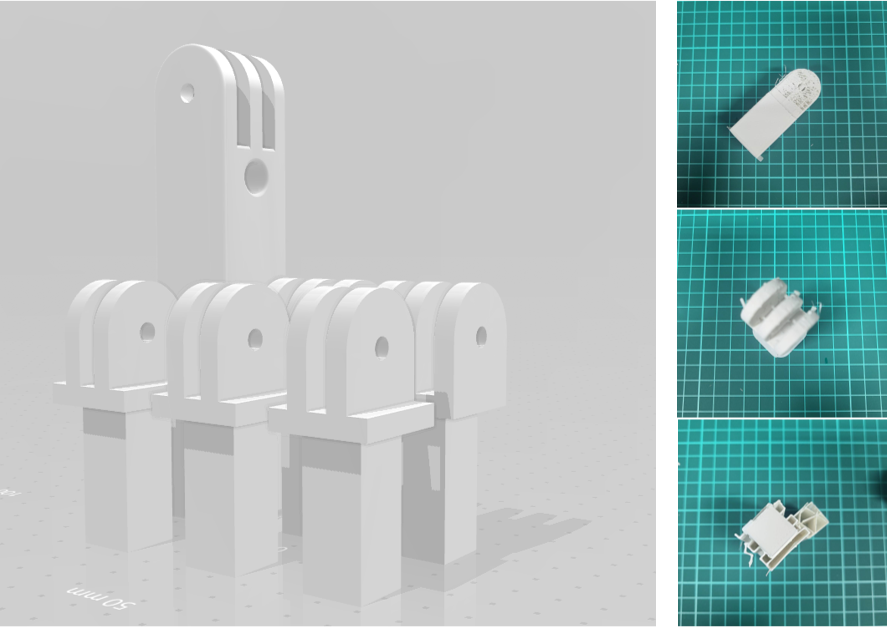

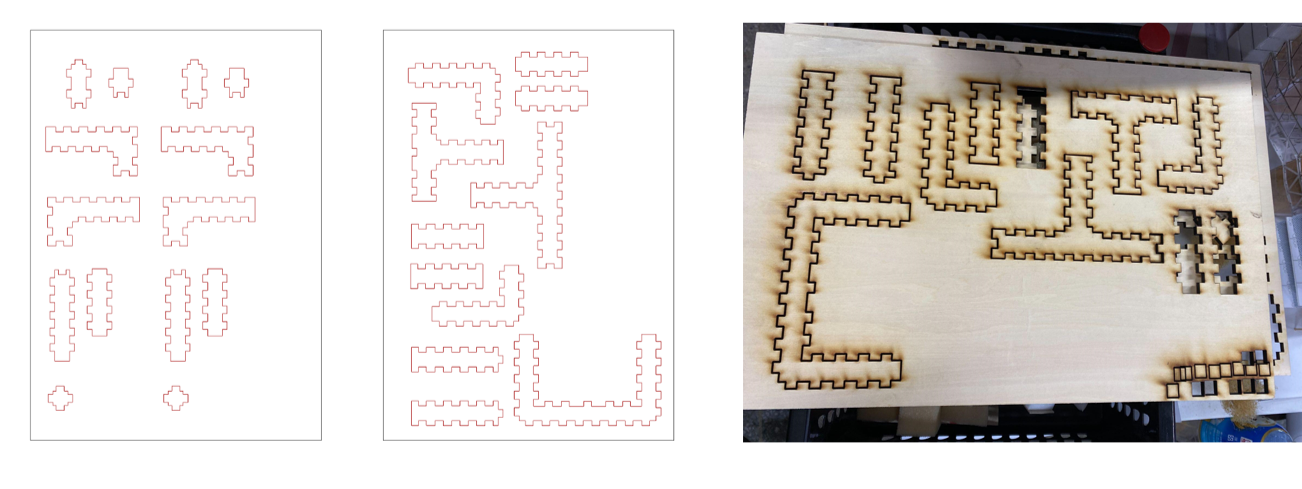

- Laser Cutter

- White-grained Wood

Cutting Power : 75% Cutting Rate : 4%

- Layout of model and result.

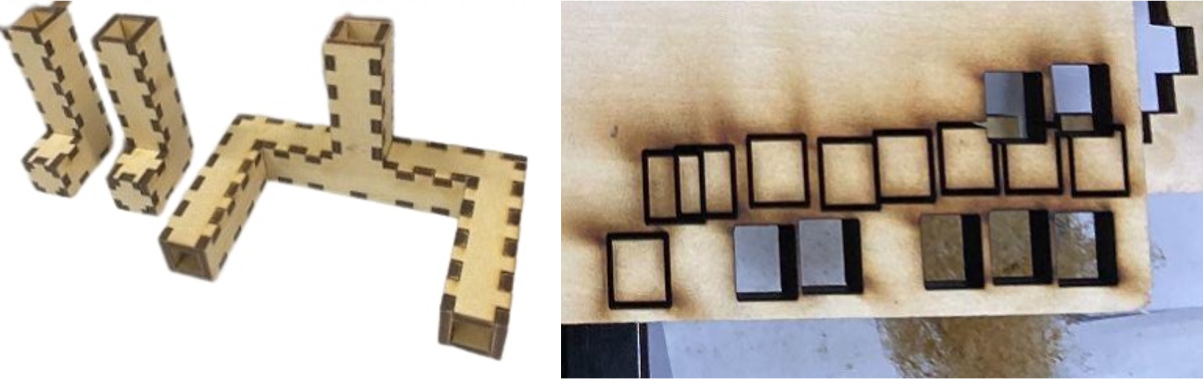

- Assembly of outcomes by laser cutter.

- The joints are still not strong enough to resist long-term using.

- After thicken the lampshade, the weight distribution unbalanced.

- The deviation of laser cutting makes the combination between body and joint just fit-in.