This repository aims at design of 1024x32 SRAM cell array (32Kbits or 4KB) with a configuration of 1.8 V operating voltage and access time less than 2.5ns using Google SkyWater SKY130 PDKs and OpenRAM memory complier.

- Introduction To SRAM Cell Design

- Setting Up Environment

- SRAM Memory Architecture

- Custom Cells for OpenRAM

- OpenRAM Configuration For SkyWater SKY130 PDKs

- Pre-Layout Schematic and Simulations

- OpenRAM Compiler Output Layout

- Future Work

- References

- Acknowledgement

- Contact Information

Today, Static Random-Access Memory (SRAM) has become a standard element of any Application Specific Integrated Circuit (ASIC), System-On-Chip (SoC), or other micro-architectures. For this wide variety of applications, SRAMs are configured using parameters like the word-length, bit lines, operating voltage, access time, and most importantly the technology node. The access time of an SRAM cell is the time require for a read or write operation of SRAM.

Manually configuring the SRAM for every change in parameter seems a slightly in-efficient and tedious task. Due to this reason, the memory compiler is used on a large scale, as it facilitates easy configuration and optimization of memory. OpenRAM, an open-source memory compiler is used for characterization and generation of SRAM designs.

This repository mentioned multiple open-source circuit schematic design, layout design, SPICE simulations tools and memory compiler. The tools used and their installation is explained in details below. The complete environemnt setup for the open-source OpenLANE RTL2GDS flow can be found here.

| Name of Tool | Description |

|---|---|

| NGSPICE | An open-source mixed-level/mixed-signal electronic spice circuit simulator. |

| Xschem | A schematic editor for VLSI/Asic/Analog custom designs, netlist backends for VHDL, Spice and Verilog. |

| Magic | An open-source VLSI Layout Tool with easy DRC options. |

For properly installing all the above mentioned tools and supporting tools to their updated version follow the below mentioned steps.(Only for Ubuntu Operating System)

$ sudo apt-get install git

$ git clone https://github.com/ShonTaware/SRAM_SKY130.git

$ cd SRAM_SKY130

To install Ngspice, Magic and Xschem at once use commands below. It can be skipped otherwise.

$ chmod +777 setup_environment.sh

$ ./setup_environment.sh

-

NGSPICE: Following commands can be used for installing only the NGSPICE tool.

$ sudo apt-get install ngspice -

Xschem: Following commands can be used for installing only the Xschem Schematic Editor tool.

$ sudo apt-get install git $ git clone https://github.com/StefanSchippers/xschem.git $ cd xschem $ ./configure $ make $ sudo make install -

Magic: Following commands can be used for installing only the Magic Layout tool.

$ sudo apt-get install git $ git clone https://github.com/RTimothyEdwards/magic.git $ cd magic $ ./configure $ make $ sudo make install

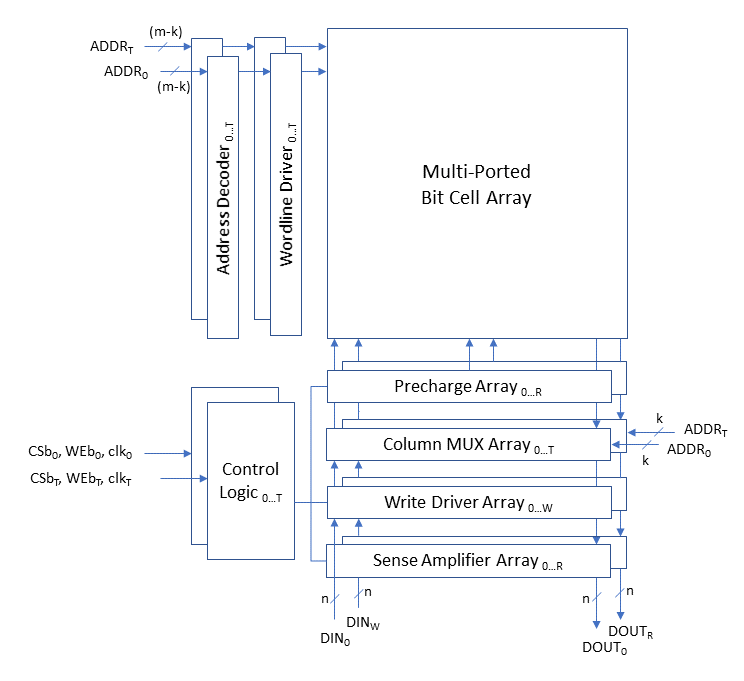

SRAM Memory is a block which designed by integrating several sub-blocks. This SRAM memory architecture for a multi-port SRAM memory is shown in the diagram below.

OpenRAM is an open-source Python framework to create the layout, netlists, timing and power models, placement and routing models, and other views necessary to use SRAMs in ASIC design. It supports integration in both commercial and open-source flows with both predictive and fabricable technologies.

OpenRAM facilitates to convert any custom design cells and design rules to various IP deliverables or formats.

OpenRAM uses some custom-designed library primitives as technology input. Since density is extremely important, the following cells are pre-designed in each technology:

- 6T cell

- Sense amplifier

- Master-slave flip-flop

- Tri-state gate

- Write driver

The detailed OpenRAM configuration, usage and issues for SKY130 pdk is documented in this section.

The detailed OpenRAM project can be found here. The steps to the installation and setup are mentioned below. The steps following will clone the OpenRAM compiler project and setup paths in .bashrc file.

$ chmod 777 openram_setup.sh

$ ./openram_setup.sh

$ source ~/.bashrc

After the installation is properly done. The directory structure of OpenRAM directory looks similar to that of mentioned.

├── OpenRAM

| ├── compiler

| ├── technologies

| ├── freepdk45 (available with compiler)

| ├── scn4m_subm (available with compiler)

| ├── sky130A

The sky130A directory is not available by default. You need to create it in order to add support for SkyWater PDK Sky130. The detailed contents and their description is explained further in the document. Also, the configure sky130A directory is included in the repository for reference. It can be found at OpenRAM/sky130A/

The OpenRAM compiler is currently available for two technologies, namely - SCMOS and FreePDK45.

For adding a new technology support to OpenRAM, a directory with name of process node should be created in technology directory of OpenRAM.

The technology directory should contains following information.

├── technology

| ├── sky130A

| ├── gds_lib

| ├── sp_lib

| ├── mag_lib (optional)

| ├── models

| ├── layers.map (can be included in another sub-directory)

| ├── tech

| ├── __init__.py

| ├── tech.py

| ├── sky130A.tech

This directory contains all the custom premade library cells in .gds file format. Following files should be listed in the gds_lib directory:

- dff.gds

- sense_amp.gds

- write_driver.gds

- cell_6t.gds

- replica_cell_6t.gds

- dummy_cell_6t.gds

This directory contains all the spice netlsits of custom premade library cells in .sp file format.

This directory contains all the NMOS and PMOS models for temperatures, voltages and process corners as per requirement. This repository contains the nfet and pfet models for all process corners operating at 1.8 V.

This file contains the layer description for gds layers. It needs to be generated from the SKY130 PDK document provided by SkyWater. You can find the document here.

The layers.map should be organized in a specific syntax. Here, each layer is given on a separate line in below mentioned format:

<layer-name> <purpose-of-layer> <GDS-layer> <GDS-purpose>

The layers.map file is added to the repository and can be found here.

This directory should contains two mandatory file listed below. Any other optional scripts can also be included if required.

tech/sky130A.techtech/tech.py

This is the technology file provided by SkyWater in the SKY130 PDKs. It needs to copied to this tech directory.

The sky130A.tech technology file is added to the repository.

This python file contains all the technology related configuration. It contains information about below mentioned paramaters.

Note: The values for any parameters given below are only for reference and not the actual values. It will be replaced in future commits with correct and appropriate values for Sky130 process node.

- Custom modules

tech_modules = module_type()

- Custom cell properties

cell_properties = cell_properties()

- Layer properties

layer_properties = layer_properties()

- GDS file info

GDS={}

GDS["unit"]=(0.001,1e-6)

GDS["zoom"] = 0.5

- Interconnect stacks

This defines the contacts and preferred directions of the metal, poly and active diffusion layers.

poly_stack = ("poly", "poly_contact", "m1")

active_stack = ("active", "active_contact", "m1")

m1_stack = ("m1", "via1", "m2")

m2_stack = ("m2", "via2", "m3")

m3_stack = ("m3", "via3", "m4")

layer_indices = {"poly": 0,

"active": 0,

"m1": 1,

"m2": 2,

"m3": 3,

"m4": 4}

# The FEOL stacks get us up to m1

feol_stacks = [poly_stack,

active_stack]

# The BEOL stacks are m1 and up

beol_stacks = [m1_stack,

m2_stack,

m3_stack]

layer_stacks = feol_stacks + beol_stacks

preferred_directions = {"poly": "V",

"active": "V",

"m1": "H",

"m2": "V",

"m3": "H",

"m4": "V"}

- Power grid

By default, the power grid is set to m3_stack i.e. it uses m3 and m4 layers for power grid.

power_grid = m1_stack # Use m1 and m2 for power grid

- GDS Layer Map

The values are similar to those listed in the layers.map file.

layer["diff"] = (65, 20)

layer["tap"] = (65, 44)

layer["nwell"] = (64, 20)

layer["dnwell"] = (64, 18)

layer["npc"] = (95, 20)

layer["licon"] = (66, 44)

layer["li"] = (67, 20)

layer["mcon"] = (67, 44)

layer["m1"] = (68, 20)

layer["via"] = (68, 44)

layer["m2"] = (69, 20)

layer["via2"] = (69, 44)

layer["m3"] = (70, 20)

layer["via3"] = (70, 44)

layer["m4"] = (71, 20)

layer["via4"] = (71, 44)

layer["m5"] = (72, 20)

...

- Layer names for external PDKs

layer_names = {}

layer["diff"] = "active"

layer["tap"] = "tap"

layer["nwell"] = "nwell"

layer["dnwell"] = "dnwell"

layer["npc"] = "npc"

layer["licon"] = "licon"

layer["li"] = "li"

layer["mcon"] = "mcon"

layer["m1"] = "m1"

layer["via"] = "via"

layer["m2"] = "m2"

layer["via2"] = "via2"

layer["m3"] = "m3"

layer["via3"] = "via3"

layer["m4"] = "m4"

layer["via4"] = "via4"

layer["m5"] = "m5"

...

- DRC/LVS Rules Setup

Note: Drc rules are required for all the layers mentioned in the interconnect stacks.

drclvs_home=os.environ.get("DRCLVS_HOME")

drc = design_rules("sky130A")

#grid size is 1/2 a lambda

drc["grid"]=0.5*_lambda_

#DRC/LVS test set_up

drc["drc_rules"] = drclvs_home+"/calibreDRC_sky130A.rul" # Replace it with "None" to skip it

drc["lvs_rules"] = drclvs_home+"/calibreLVS_sky130A.rul" # Replace it with "None" to skip it

drc["layer_map"] = os.environ.get("OPENRAM_TECH")+"/scn3me_subm/layers.map"

# minwidth_tx with contact (no dog bone transistors)

drc["minwidth_tx"] = 4*_lambda_

drc["minlength_channel"] = 2*_lambda_

# Minimum spacing between wells of different type (if both are drawn)

drc["pwell_to_nwell"] = 0

# Minimum width

drc.add_layer("nwell",

width = 12*_lambda_,

spacing = 6*_lambda_)

# Enclosure

drc.add_enclosure("m1",

layer = "via1",

enclosure = _lambda_)

...

- Technology parameter

_lambda_ = 0.2

#technology parameter

parameter = {}

parameter["min_tx_size"] = 4*_lambda_

parameter["beta"] = 2

# These 6T sizes are used in the parameterized bitcell.

parameter["6T_inv_nmos_size"] = 8*_lambda_

parameter["6T_inv_pmos_size"] = 3*_lambda_

parameter["6T_access_size"] = 4*_lambda_

-

Spice Simulation Parameters

- Spice model info

# spice model info spice = {} spice["sky130_fd_pr__nfet_01v8"] = "nmos" spice["sky130_fd_pr__pfet_01v8"] = "pmos"- Map of corners to model files

# This is a map of corners to model files SPICE_MODEL_DIR=os.environ.get("SPICE_MODEL_DIR") spice["fet_models"] = {"TT": [SPICE_MODEL_DIR + "/nom/pmos.sp", SPICE_MODEL_DIR + "/nom/nmos.sp"], "FF": [SPICE_MODEL_DIR + "/ff/pmos.sp", SPICE_MODEL_DIR + "/ff/nmos.sp"], "FS": [SPICE_MODEL_DIR + "/ff/pmos.sp", SPICE_MODEL_DIR + "/ss/nmos.sp"], "SF": [SPICE_MODEL_DIR + "/ss/pmos.sp", SPICE_MODEL_DIR + "/ff/nmos.sp"], "SS": [SPICE_MODEL_DIR + "/ss/pmos.sp", SPICE_MODEL_DIR + "/ss/nmos.sp"], "ST": [SPICE_MODEL_DIR + "/ss/pmos.sp", SPICE_MODEL_DIR + "/nom/nmos.sp"], "TS": [SPICE_MODEL_DIR + "/nom/pmos.sp", SPICE_MODEL_DIR + "/ss/nmos.sp"], "FT": [SPICE_MODEL_DIR + "/ff/pmos.sp", SPICE_MODEL_DIR + "/nom/nmos.sp"], "TF": [SPICE_MODEL_DIR + "/nom/pmos.sp", SPICE_MODEL_DIR + "/ff/nmos.sp"], }- Spice stimulus related variables

spice["feasible_period"] = 10 # estimated feasible period in ns spice["supply_voltages"] = [4.5, 5.0, 5.5] # Supply voltage corners in [Volts] spice["nom_supply_voltage"] = 5.0 # Nominal supply voltage in [Volts] spice["rise_time"] = 0.05 # rise time in [Nano-seconds] spice["fall_time"] = 0.05 # fall time in [Nano-seconds] spice["temperatures"] = [0, 25, 100] # Temperature corners (celcius) spice["nom_temperature"] = 25 # Nominal temperature (celcius)- Analytical delay parameters

spice["nom_threshold"] = 1.3 # Nominal Threshold voltage in Volts spice["wire_unit_r"] = 0.075 # Unit wire resistance in ohms/square spice["wire_unit_c"] = 0.64 # Unit wire capacitance ff/um^2 spice["min_tx_drain_c"] = 0.7 # Minimum transistor drain capacitance in ff spice["min_tx_gate_c"] = 0.1 # Minimum transistor gate capacitance in ff spice["dff_setup"] = 9 # DFF setup time in ps spice["dff_hold"] = 1 # DFF hold time in ps spice["dff_in_cap"] = 9.8242 # Input capacitance (D) [Femto-farad] spice["dff_out_cap"] = 2 # Output capacitance (Q) [Femto-farad]- Analytical power parameters

spice["bitcell_leakage"] = 1 # Leakage power of a single bitcell in nW spice["inv_leakage"] = 1 # Leakage power of inverter in nW spice["nand2_leakage"] = 1 # Leakage power of 2-input nand in nW spice["nand3_leakage"] = 1 # Leakage power of 3-input nand in nW spice["nand4_leakage"] = 1 # Leakage power of 4-input nand in nW spice["nor2_leakage"] = 1 # Leakage power of 2-input nor in nW spice["dff_leakage"] = 1 # Leakage power of flop in nW spice["default_event_frequency"] = 100 # Default event activity of every gate. MHz -

Logical Effort relative values for the Handmade cells

parameter["le_tau"] = 18.17 # In pico-seconds.

parameter["min_inv_para_delay"] = 2.07 # In relative delay units

parameter["cap_relative_per_ff"] = .91 # Units of Relative Capacitance/ Femto-Farad

parameter["dff_clk_cin"] = 27.5 # In relative capacitance units

parameter["6tcell_wl_cin"] = 2 # In relative capacitance units

parameter["sa_en_pmos_size"] = 24 * _lambda_

parameter["sa_en_nmos_size"] = 9 * _lambda_

parameter["sa_inv_pmos_size"] = 18 * _lambda_

parameter["sa_inv_nmos_size"] = 9 * _lambda_

parameter["bitcell_drain_cap"] = 0.2 # In Femto-Farad, approximation of drain capacitance

- Technology Tool Preferences

drc_name = "magic"

lvs_name = "netgen"

pex_name = "magic"

The sample OpenRAM configurations are added to the repository. To use it, copy the sky130A directory into the technology directory of OpenRAM.

cp -rf OpenRAM/sky130A $OPENRAM_TECH/

- Sample 2: It modified technology files, mag_lib, sp_lib, gds_lib, tech.py and layers.map files.

A configuration file need to be generated in python which contains all parameters required for the compiler. Every parameter mentioned in the configuration file overrides the default value of the parameter. If a parameter is not mentioned in the file, compiler will take a default value.

A template file named myconfig_sky130.py is added in the repository. The file contains parameters as given below.

# Data word size

word_size = 32

# Number of words in the memory

num_words = 1024

# Technology to use in $OPENRAM_TECH

tech_name = "sky130A"

# You can use the technology nominal corner only

#nominal_corner_only = True

# Or you can specify particular corners

# Process corners to characterize

process_corners = ["TT"]

# Voltage corners to characterize

supply_voltages = [ 1.8 ]

# Temperature corners to characterize

# temperatures = [ 0, 25 100]

# Output directory for the results

output_path = "temp"

# Output file base name

output_name = "sram_{0}_{1}_{2}".format(word_size,num_words,tech_name)

# Disable analytical models for full characterization (WARNING: slow!)

# analytical_delay = False

OpenRAM is invoked using the following command

python3 $OPENRAM_HOME/openram.py myconfig_sky130

or

python3 $OPENRAM_HOME/openram.py myconfig_sky130.py

The FEOL(Front-End-of-line) in default configuration of OpenRAM includes a contact named poly_contact present between the polysilicon and metal1 layers. But SKY130 does not have a direct contact available between polysilicon and metal1 layers. Instead, it has a pcontact between polysilicon and locali (local interconnect) and further, contact licon between locali and metal1.

Therefore, feol_stacks mentioned above will have an extra entry for licon along with poly_contact and active_contact. Each entry in the feol_stack is a three entry tuple data-structure in python given by (<lower-layer>, <contact-from-lower-to-upper>, <upper-layer>)

poly_stack = ("poly", "pcontact", "li")

li_stack = ("li", "licon", "m1")

# The FEOL stacks get us up to m1

feol_stacks = [poly_stack,

li_stack,

active_stack]

Sky130 do not consist any layer named active or active_contact as that in case of other default technologies.

The default active layer corresponds to diff (active diffusion) layer in SKY130. Similarly, the default active_contact layer corresponds to tap layer in SKY130.

layer["diff"] = (65, 20)

layer["tap"] = (65, 44)

layer["diff"] = "active"

layer["tap"] = "tap"

One of the major issue in OpenRAM configuration is, the SKY130 PDK do not have boundary layer definition for drawing purpose in the GDS layer description provided by SkyWater. But OpenRAM compiler expects a boundary layer to compute the cell area and to avoid overlapping of cells.

The compiler correctly placed the routing layers (p-diffusion, ndiffusion and local interconnect) but does not place a valid contact(p-diff contact or n-diff contact).

Note: We are currently working on resolving this issue. The solution will be updated to repository soon.

As the name says, 6T SRAM cell consists of 6 MOSFETS - 2 PMOS and 4 NMOS. It is design by cross coupling two CMOS inverters which hold the bit, and two access transistor for enabling the access to the cross coupled inverters.

The figure below shows the schematic of the generic 6T SRAM cell. Here, M1, M2 make the first inverter; M3, M4 make the second inverter and M5, M6 are the access transistors.

The read operation is a critical one in SRAM cell. This is becuase, before enabling the access transistors, the bit-lines are first pre-charged to high logic. Depending upon the bit store, one of the bit-line is pulled back to logic low when the access transistors are enabled.

$ ngspice Prelayout/Spice_models/SRAM_6T_Cell_read.spice

The bit to be written is first loaded to the bit-line and its inverted bit is loaded on the other bit-line. Once the access transistors are enabled the bit values on bit-lines are over-written on the inverter logic.

$ ngspice Prelayout/Spice_models/SRAM_6T_Cell_write.spice

-

Static Noise Margin

Static noise margin (SNM) is a key figure of merit for an SRAM cell. It can be extracted by nesting the largest possible square in the two voltage transfer curves (VTC) of the two CMOS inverters involved. The SNM is defined as the side-length of the square (i.e. diagonal-length), given in volts. When an external DC noise is larger than the SNM, the state of the SRAM cell can change and data is lost.

- Hold SNM

$ ngspice Prelayout/Spice_models/SRAM_Cell_hold_snm.spice

SNMlow = 1.1112 V

Hold SNM = min(SNMhigh, SNMlow) = 1.0879 V

- Read SNM

$ ngspice Prelayout/Spice_models/SRAM_Cell_read_snm.spice

SNMlow = 0.4294 V

Read SNM = min(SNMhigh, SNMlow) = 0.4294 V

- Write SNM

$ ngspice Prelayout/Spice_models/SRAM_Cell_write_snm.spice

-

N-Curve N-curve is a metric used for inline testers. It gives information for both voltage and current, and in addition it has no voltage scaling delimiter as found in SNM approach. It also has the complete information about the SRAM stability and also write ability in a single plot. N-curve can be further extended to power metrics in which both the voltage and current information are taken into consideration to provide better stability analysis of the SRAM cell.

$ ngspice Prelayout/Spice_models/SRAM_Cell_n_curve.spice-

Static Voltage Noise Margin (SVNM): It is the voltage difference between point A and B. It indicates the maximum tolerable DC noise voltage of the cell before its content changes.

SVNM = 0.5644 V -

Static Current Noise Margin (SINM): It is the additional current information provided by the N-curve, namely the peak current located between point A and B. It can also be used to characterize the cell read stability.

SINM = 122.6 uA

Note: For better read stability, SVNM and SINM must be high value.

-

Write-Trip Voltage (WTV): It is the voltage difference between point C and B. It is the voltage drop needed to flip the internal node “1” of the cell with both the bit-lines clamped to VDD.

WTV = 0.9422 V -

Write-Trip Current (WTI): It is the negative current peak between point C and B. It is the amount of current needed to write the cell when both bit-lines are kept at VDD.

WTI = -30.869 uA

-

This circuit block is used to pre-charge the bit-lines to Vdd or high logic during a read operation.

Shown below is the schematic and simulation of the Pre-charge circuit.

$ ngspice Prelayout/Spice_models/precharge_circuit.spice

Sense Amplifiers in SRAM generally a Differential Voltage Amplifier. They form a very important part of SRAM memory as these amplifiers define the robustness of the bit-lines sensing. The function of sense amplifier is to amplify the very small analog differential voltage between the bit-lines during a read operation and provide a digital output. This effectively reduces the time required for the read operation, as each individual cell need not fully discharge the bit line.

- if bit > bit_bar, output is 1

- if bit < bit_bar, output is 0

Shown below is the schematic and simulation of a Sense Amplifier.

$ ngspice Prelayout/Spice_models/sense_amplifier.spice

As discussed in read operation, the bit-lines are pre-charged to Vdd during the read operation. If a write operation occurs, one of the bit-lines should driven back to low logic before enabling access transistors. Write drivers are used for this purpose.

Shown below is the schematic and simulation of a Write Driver.

$ ngspice Prelayout/Spice_models/write_driver.spice

Tri-state buffer is a normal buffer with an extra enable input. Whenever, the enable input is high, tri-state buffer behaves as a normal buffer, otherwise it will either give high impedance or low logic as output.

Shown below is the schematic and simulation of a Tri-State Buffer.

$ ngspice Prelayout/Spice_models/tristate_buffer.spice

Shown below is the schematic and simulation of a Positive Edge triggered D-Flip-Flop.

$ ngspice Prelayout/Spice_models/d_ff.spice

1-bit SRAM comprises of a 6T SRAM cell, a sense amplifier, a write driver and a pre-charge circuit.

-

Read Operation

$ ngspice Prelayout/Spice_models/SRAM_1bit_read.spice

-

Write Operation

$ ngspice Prelayout/Spice_models/SRAM_1bit_write.spice

The Layout for 2 X 16 SRAM cell is show below. The detailed report can be found here

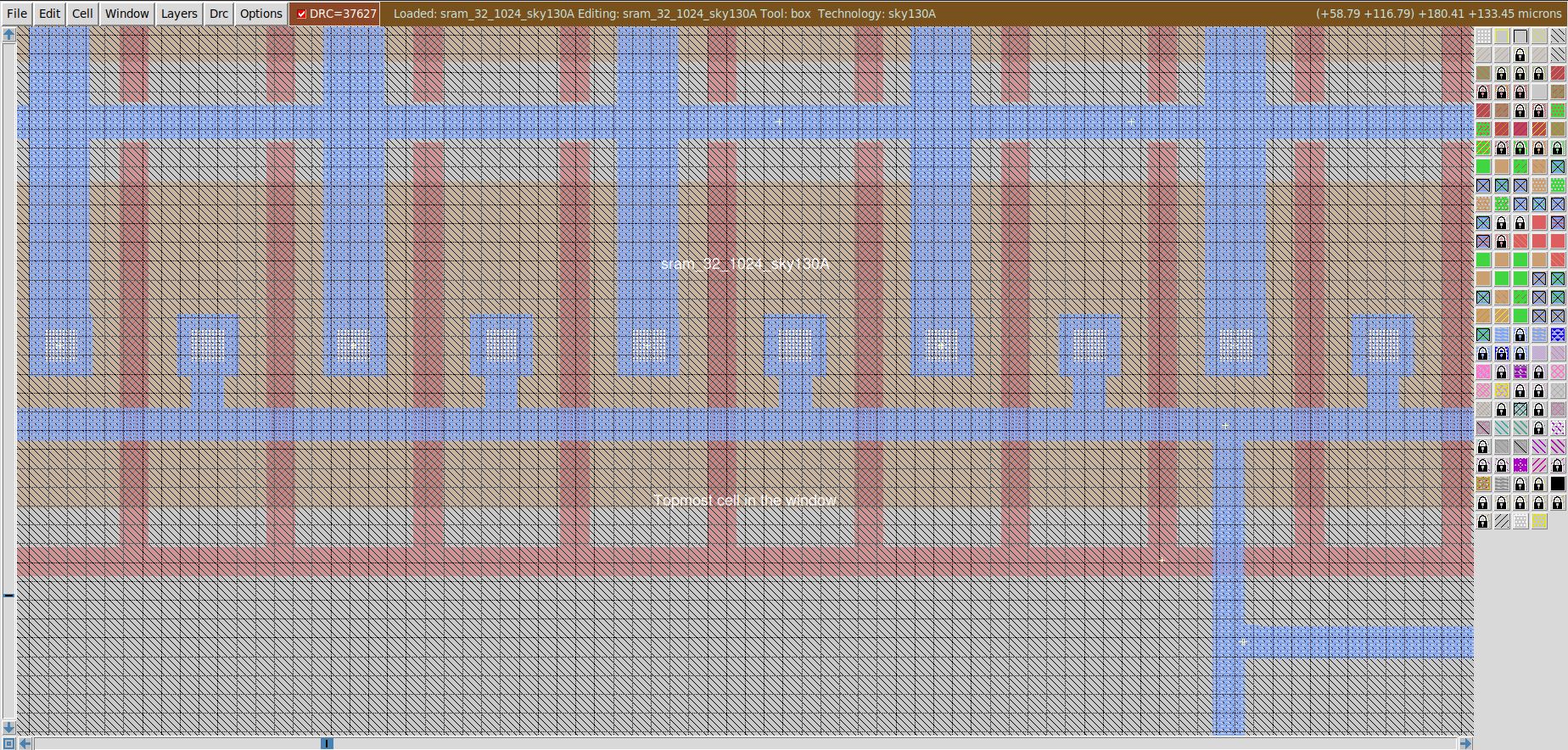

The Layout for 32 X 1024 SRAM cell is show below. The detailed report can be found here

Perform post-layout design and simulations. Also, configure the OpenRAM for new Sky130 PDKs and custom cells.

- VLSI System Design: https://www.vlsisystemdesign.com/

- Efabless OpenLANE: https://github.com/efabless/openlane

- OpenRAM: https://vlsida.github.io/OpenRAM/

- M. Guthaus et al., “OpenRAM: An open-source memory compiler,” 2016 IEEE/ACM International Conference on Computer-Aided Design(ICCAD), Austin, TX, 2016, pp. 1-6.

- Nickson Jose: Standard cell design and characterization using openlane flow

- Kunal Ghosh, Co-founder, VSD Corp. Pvt. Ltd.

- Matthew R. Guthaus, University of California, Santa Cruz.

- Pradeepkumar S K, Assistant Professor, Electronics and Communication Engineering, Kalpataru Institute of Technology, Tiptur, Karnataka.

- Shon Taware, M.Tech. Embedded Systems and VLSI Design

- Kunal Ghosh, Co-founder, VSD Corp. Pvt. Ltd.