OS / Architecture / Machine Tool Matrix

API Description and Sample Responses

This solution is built on top of Fanuc Focas libraries for interfacing with Fanuc controllers and publishing data to a MQTT broker or another target.

The primary goal of this solution is to maintain the machine data in its native source format with slight transformations to make it more human readable at the target. The intention behind this approach is to allow the developer to reference original Focas API documentation further downstream to aid in their transformation and translation efforts. Concepts in the base-driver repository can be reused to create structured drivers for other protocols.

Below illustrates Fanuc NC Guide output visualized through MQTT Explorer.

Below illustrates Fanuc 0i-TF production output.

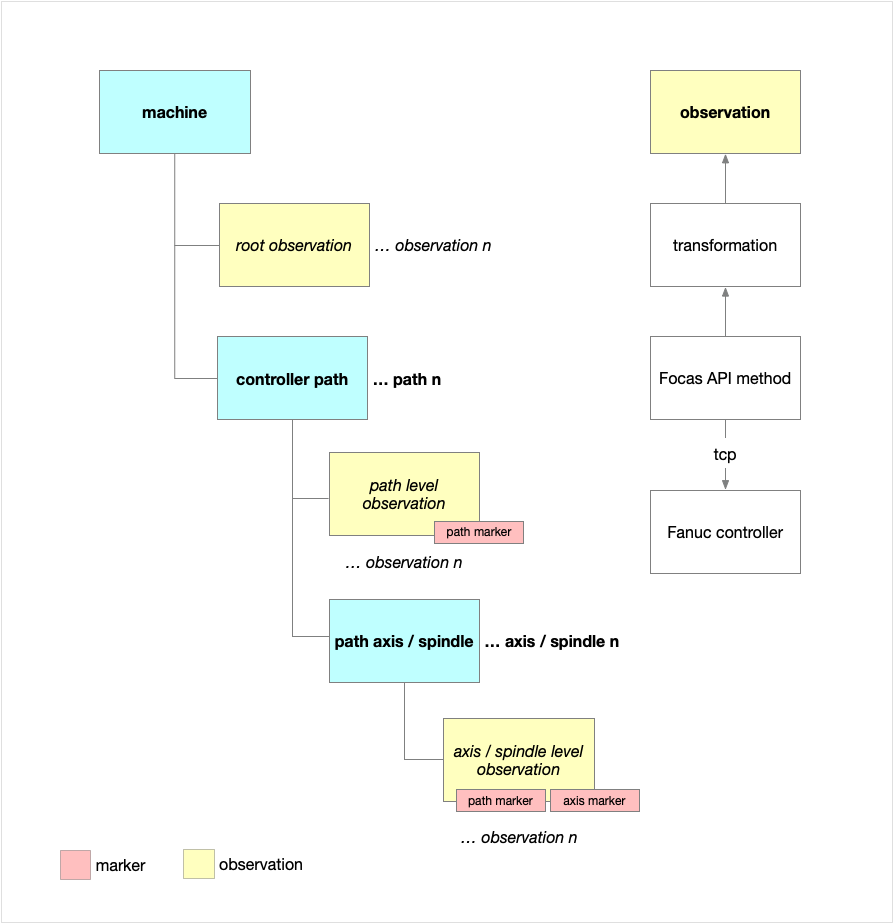

Observations can be single data points, such as axis absolute position or motor temperature. Observations can also be more compound such as the health of a spindle which would package multiple relevant data points into a single observation payload. Results of calls into the Focas library highly depend on the context they are invoked in. For example, retrieving the position of an axis on the second execution path of the controller, requires that the second path is made active and the appropriate axis is called out when making the call. This hierarchy is captured in the suggested topic structure below.

fanuc/{machine-id}/{observation-name}

fanuc/{machine-id}-all/{observation-name}

fanuc/{machine-id}/{observation-name}/{controller-execution-path-number}

fanuc/{machine-id}-all/{observation-name}/{controller-execution-path-number}

fanuc/{machine-id}/{observation-name}/{controller-execution-path-number}/{machine-axis-name / machine-spindle-name}

fanuc/{machine-id}-all/{observation-name}/{controller-execution-path-number}/{machine-axis-name / machine-spindle-name}

fanuc/{machine-id}/PING

fanuc/{machine-id}-all/PING

fanuc/DISCO

Data deltas are published to MQTT broker as retained messages. This means that any newly connected client will only receive the latest data for each observation.

Below is an example of native cnc_sysinfo invocation response data and the corresponding sys_info observation transformed data.

Native data from controller:

{

"addinfo": 1090,

"max_axis": 32,

"cnc_type": [

" ",

"0"

],

"mt_type": [

" ",

"M"

],

"series": [

"D",

"4",

"F",

"1"

],

"version": [

"3",

"0",

".",

"0"

],

"axes": [

"0",

"3"

]

}

Data after transformation:

{

"addinfo": 1090,

"max_axis": 32,

"cnc_type": " 0",

"mt_type": " M",

"series": "D4F1",

"version": "30.0",

"axes": "03"

}

Data as published to the broker:

fanuc/sim/sys_info

fanuc/sim-all/sys_info

{

"observation": {

"time": 1620485344410,

"machine": "sim",

"name": "sys_info",

"marker": {}

},

"source": {

"method": "cnc_sysinfo",

"invocationMs": 25,

"data": {}

},

"delta": {

"time": "00:00:01.4453544",

"data": {

"max_axis": 32,

"cnc_type": " 0",

"mt_type": " M",

"series": "D4F1",

"version": "30.0",

"axes": "03"

}

}

}

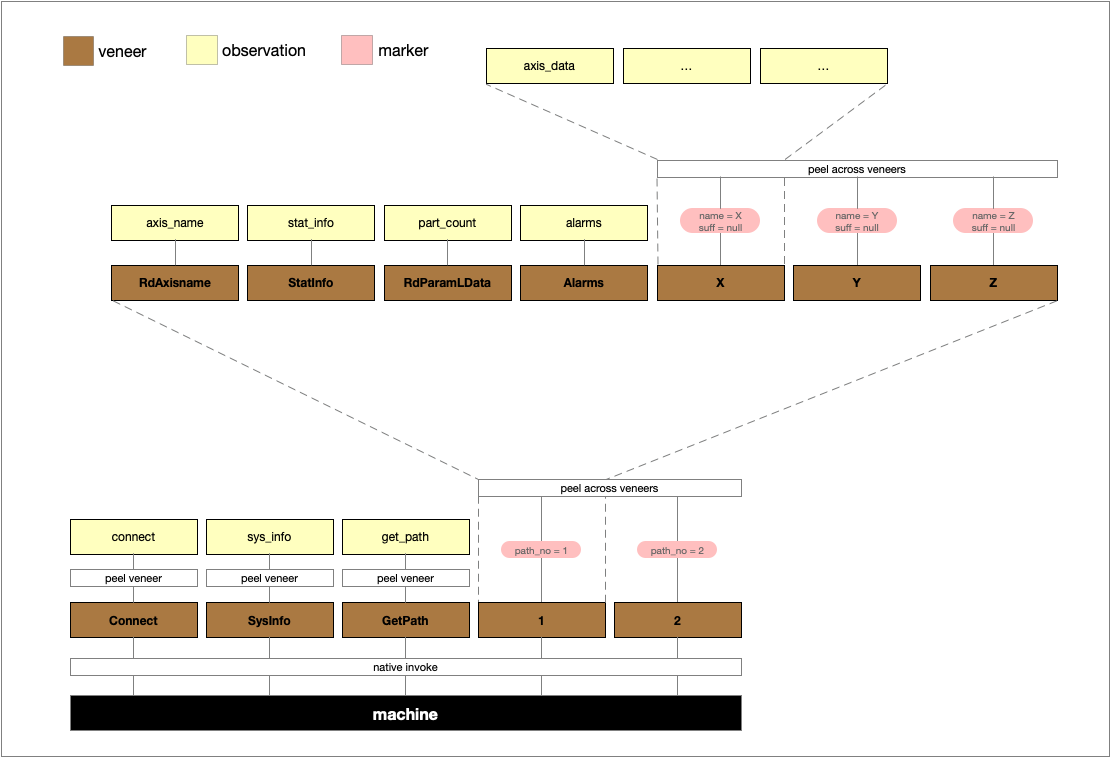

A Machine instance includes:

- native connectivity information

- data output post-processor (

Handler) - data collection strategy (

Collector) - data collection transformation (

Veneer)

A Handler is an observation post-processor and interface to target systems.

A Collector is a strategy to apply and peel veneers to reveal observations from native data in near real-time.

A Veneer is a thin transformation layer. When peeled, each veneer reveals an observation. Veneers can be applied/peeled as a whole. Veneers can be sliced and applied/peeled across logical boundaries (e.g. path, axis, spindle). Atomic values should be used for slicing veneers. Sliced veneers must be marked before peeling in order to convey the logical hierarchy of the observation to downstream systems.

Example of an observation marker for spindle 'S' on execution path '1'.

"marker": [

{

"path_no": 1

},

{

"name": "S",

"suff1": "",

"suff2": ""

}

]The act of applying veneers in a logical manner in order to bind transformation logic to an observation.

The act of peeling veneers in order to execute transformations and reveal observations.

During collector initialization, each call to ApplyVeneer binds a transformation class to an observation name.

public override void Initialize()

{

_machine.ApplyVeneer(typeof(fanuc.veneers.Connect), "connect");

_machine.ApplyVeneer(typeof(fanuc.veneers.SysInfo), "sys_info");

}

The collector is processed at set intervals.

public override void Collect()

{

dynamic connect = _machine.Platform.Connect();

_machine.PeelVeneer("connect", connect);

A connection is established to the Fanuc controller and the call to PeelVeneer reveals the connect observation. The Connect Veneer instance is responsible for transforming the native Focas response where appropriate, comparing it to the last value seen, and invoking the dataArrived and dataChanged actions. Every arrived data is available via the Machine.Veneers.OnDataArrival<Veneers, Veneer> delegate. Changed data is available via the Machine.Veneers.OnDataChange<Veneers, Veneer> delegate. Similarly, errors bubble up to Machine.Veneers.OnError<Veneers, Veneer>.

if (connect.success)

{

dynamic info = _machine.Platform.SysInfo();

_machine.PeelVeneer("sys_info", info);

Next, the sys_info observation is revealed. A call to Focas cnc_sysinfo is made via the Machine.Platform.SysInfo wrapper method. The SysInfo Veneer instance then transforms native character arrays to strings, for easier readability.

dynamic disconnect = _machine.Platform.Disconnect();

}

LastSuccess = connect.success;

}

Finally, the connection to the Fanuc controller is broken and the success of the Collect iteration captured.

Initialization of the Basic01 Collector strategy binds several Veneer types to named observations.

_machine.ApplyVeneer(typeof(fanuc.veneers.Connect), "connect");

_machine.ApplyVeneer(typeof(fanuc.veneers.CNCId), "cnc_id");

_machine.ApplyVeneer(typeof(fanuc.veneers.RdTimer), "power_on_time");

_machine.ApplyVeneer(typeof(fanuc.veneers.RdParamLData), "power_on_time_6750");

_machine.ApplyVeneer(typeof(fanuc.veneers.SysInfo), "sys_info");

_machine.ApplyVeneer(typeof(fanuc.veneers.GetPath), "get_path");

Each data collection iteration retrieves data from the Fanuc controller and reveals individual observations.

dynamic connect = _machine.Platform.Connect();

_machine.PeelVeneer("connect", connect);

if (connect.success)

{

dynamic cncid = _machine.Platform.CNCId();

_machine.PeelVeneer("cnc_id", cncid);

dynamic poweron = _machine.Platform.RdTimer(0);

_machine.PeelVeneer("power_on_time", poweron);

dynamic poweron_6750 = _machine.Platform.RdParam(6750, 0, 8, 1);

_machine.PeelVeneer("power_on_time_6750", poweron_6750);

dynamic info = _machine.Platform.SysInfo();

_machine.PeelVeneer("sys_info", info);

dynamic paths = _machine.Platform.GetPath();

_machine.PeelVeneer("get_path", paths);

dynamic disconnect = _machine.Platform.Disconnect();

}

LastSuccess = connect.success;

Example: Basic02

Example: Basic03

Example: Basic04

Example: Basic05

Example: Basic06

Example: Basic07

Example: Basic08

This example departs from previous ones based on the emerged pattern of data collection at different levels in the Fanuc component hierarchy as it relates to the Focas windowing function calls. Data collection is broken down by path, axis, and spindle with the boiler plate implemented in FanucCollector2 base class.

using System.Threading.Tasks;

using l99.driver.@base;

namespace l99.driver.fanuc.collectors

{

public class Basic08 : FanucCollector2

{

public Basic08(Machine machine, int sweepMs = 1000) : base(machine, sweepMs)

{

}

// global machine observations

public override async Task InitRootAsync()

{

apply(typeof(fanuc.veneers.CNCId), "cnc_id");

apply(typeof(fanuc.veneers.RdParamLData), "power_on_time");

}

// execution path observations

public override async Task InitPathsAsync()

{

apply(typeof(fanuc.veneers.SysInfo), "sys_info");

apply(typeof(fanuc.veneers.StatInfo), "stat_info");

apply(typeof(fanuc.veneers.Figures), "figures");

apply(typeof(fanuc.veneers.GCodeBlocks), "gcode_blocks");

}

// axis and spindle observations

public override async Task InitAxisAndSpindleAsync()

{

apply(typeof(fanuc.veneers.RdDynamic2_1), "axis_data");

apply(typeof(fanuc.veneers.RdActs2), "spindle_data");

}

//

// collection sweep

//

// begin =>

// root/global =>

// walk each execution path =>

// walk each axis in execution path =>

// walk each spindle in execution path =>

// end =>

// sleep =>

// begin ...

//

public override async Task<bool> CollectBeginAsync()

{

return await base.CollectBeginAsync();

}

// reveal global machine observations

public override async Task CollectRootAsync()

{

// single data point observation

//

// set_native_and_peel

// 1. cache focas returned value as "cnc_id"

// 2. reveal observation bound by "cnc_id" in InitRootAsync function

//

await set_native_and_peel("cnc_id", await _platform.CNCIdAsync());

await set_native_and_peel("power_on_time", await _platform.RdParamDoubleWordNoAxisAsync(6750));

}

// reveal execution path observations

public override async Task CollectForEachPathAsync(short current_path, dynamic path_marker)

{

await set_native_and_peel("sys_info", await _platform.SysInfoAsync());

await set_native_and_peel("stat_info", await _platform.StatInfoAsync());

await set_native_and_peel("figures", await _platform.GetFigureAsync(0, 32));

// compound observation

//

// set_native

// 1. cache focas returned value as "blkcount", "actpt", "execprog"

//

// peel

// 1. reveal observation bound by "gcode_blocks" in InitPathAsync function

// "blkcount", "actpt", and "execprog" data is fed into the transformation logic

//

await peel("gcode_blocks",

await set_native("blkcount", await _platform.RdBlkCountAsync()),

await set_native("actpt", await _platform.RdActPtAsync()),

await set_native("execprog", await _platform.RdExecProgAsync(128)));

}

// reveal axis observations

public override async Task CollectForEachAxisAsync(short current_axis, dynamic axis_split, dynamic axis_marker)

{

//

// get

// retrieve "figures" value from cache previously set in CollectForEachPathAsync

//

await peel("axis_data",

await set_native("axis_dynamic", await _platform.RdDynamic2Async(current_axis, 44, 2)),

get("figures"),

current_axis - 1);

}

// reveal spindle observations

public override async Task CollectForEachSpindleAsync(short current_spindle, dynamic spindle_split, dynamic spindle_marker)

{

await set_native_and_peel("spindle_data", await _platform.Acts2Async(current_spindle));

}

public override async Task CollectEndAsync()

{

await base.CollectEndAsync();

}

}

}handler_type: l99.driver.fanuc.handlers.SplunkMetric, fanuc

handler_type: l99.driver.fanuc.handlers.InfluxLine, fanuc

handler_type: l99.driver.fanuc.handlers.SparkplugB, fanuc

The config.yml file contains runtime information about each Focas endpoint and it target MQTT broker.

machines:

- id: sim

enabled: !!bool true

type: l99.driver.fanuc.FanucMachine, fanuc

strategy_type: l99.driver.fanuc.collectors.Basic06, fanuc

handler_type: l99.driver.fanuc.handlers.Native, fanuc

sweep_ms: !!int 1000

net_ip: 10.20.30.101

net_port: !!int 8193

net_timeout_s: !!int 2

broker:

enabled: !!bool false

net_ip: 10.20.30.102

net_port: !!int 1883

auto_connect: !!bool true

publish_status: !!bool true

publish_arrivals: !!bool true

publish_changes: !!bool true

publish_disco: !!bool true

disco_base_topic: fanuc

- id: naka

enabled: !!bool false

type: l99.driver.fanuc.FanucMachine, fanuc

strategy_type: l99.driver.fanuc.collectors.Basic06, fanuc

handler_type: l99.driver.fanuc.handlers.Native, fanuc

sweep_ms: !!int 1000

net_ip: 172.16.13.100

net_port: !!int 8193

net_timeout_s: !!int 5

broker:

enabled: !!bool false

net_ip: 172.16.10.3

net_port: !!int 1883

auto_connect: !!bool true

publish_status: !!bool true

publish_arrivals: !!bool true

publish_changes: !!bool true

publish_disco: !!bool true

disco_base_topic: fanuc

(for aarch64, see Docker)

Follow .NET Core SDK installation instructions here: https://sukesh.me/2020/07/07/how-to-install-net-core-on-raspberry-pi/

Clone the repository, build the project, and run it.

export DOTNET_ROOT=$HOME/dotnet

export PATH=$PATH:$HOME/dotnet

cd ~

git clone --recurse-submodules -j8 https://github.com/Ladder99/fanuc-driver.git

cd fanuc-driver/fanuc

dotnet build /nowarn:CS0618 /nowarn:CS8632 /nowarn:CS1998 -p:DefineConstants=ARMV7

./bin/Debug/netcoreapp3.1/fanuc

Follow .NET Core SDK installation instructions here: TODO

Clone the repository, build the project, and run it.

export DOTNET_ROOT=$HOME/dotnet

export PATH=$PATH:$HOME/dotnet

cd ~

git clone --recurse-submodules -j8 https://github.com/Ladder99/fanuc-driver.git

cd fanuc-driver/fanuc

dotnet build /nowarn:CS0618 /nowarn:CS8632 /nowarn:CS1998 -p:DefineConstants=LINUX64

./bin/Debug/netcoreapp3.1/fanuc

Install JetBrains Rider and build for 32-bit CPU.

Install Docker and docker-compose.

sudo apt-get update

sudo apt-install curl

curl -sSL https://get.docker.com | sh

sudo usermod -aG docker $(whoami)

newgrp docker

sudo systemctl enable docker

sudo systemctl start docker

sudo apt install python3-pip

sudo apt-get -y install libffi-dev libssl-dev python3-dev python3 python3-pip

sudo pip3 install docker-compose

sync

NLog file used: ~/fanuc-driver/docker/nlog.config

Config file used: ~/fanuc-driver/docker/config.yml

Build container:

cd ~

git clone --recurse-submodules -j8 https://github.com/Ladder99/fanuc-driver.git

cd fanuc-driver

docker build -f Dockerfile.ARM --tag=ladder99/fanuc-driver:latest .

NLog file used: ~/fanuc-driver/docker/nlog.config

Config file used: ~/fanuc-driver/docker/config.yml

Build container:

cd ~

git clone --recurse-submodules -j8 https://github.com/Ladder99/fanuc-driver.git

cd fanuc-driver

docker build -f Dockerfile.LINUX64 --tag=ladder99/fanuc-driver:latest .

docker run -it ladder99/fanuc-driver:latest

Run fanuc-driver, Mosquitto MQTT broker, and Streamsheets:

NLog file used: ~/fanuc-volumes/fanuc-driver/nlog.config

Config file used: ~/fanuc-volumes/fanuc-driver/config.yml

cd ~

git clone --recurse-submodules -j8 https://github.com/Ladder99/fanuc-driver.git

mkdir -p fanuc-volumes/fanuc-driver

cp fanuc-driver/docker/nlog.config fanuc-volumes/fanuc-driver/nlog.config

cp fanuc-driver/docker/config.yml fanuc-volumes/fanuc-driver/config.yml

mkdir -p fanuc-volumes/mosquitto/config

mkdir -p fanuc-volumes/mosquitto/data

mkdir -p fanuc-volumes/mosquitto/log

cp fanuc-driver/docker/mosquitto.conf fanuc-volumes/mosquitto/config/mosquitto.conf

cd fanuc-driver/docker

docker-compose up -d

Naviagate to http://raspberrypi.local:8081 for the Streamsheets interface. After getting to know Streamsheets, you will be able to create all kinds of Fanuc spreadsheets!

// FIX: Mongo unclean shutdown on reboot.